Vlfe

- 4

- 0

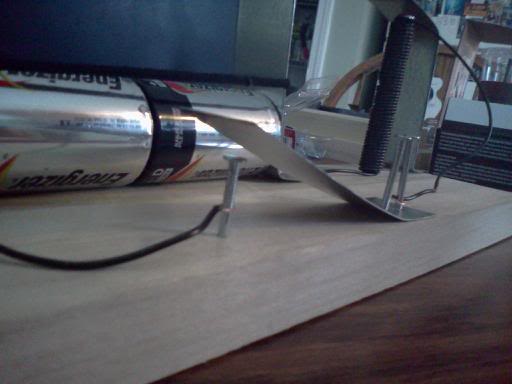

Here is how I set it up:

I am using 22 gauge hookup wire, all of the metal is steel (magnetic), and the nail in the electromagnet part is iron.

Am I connecting the wires to the wrong metal parts, or doing so incorrectly? I found this set up at: http://w1tp.com/perbuild.htm

Please help, I am so lost :(

I am using 22 gauge hookup wire, all of the metal is steel (magnetic), and the nail in the electromagnet part is iron.

Am I connecting the wires to the wrong metal parts, or doing so incorrectly? I found this set up at: http://w1tp.com/perbuild.htm

Please help, I am so lost :(