shafqut

- 3

- 0

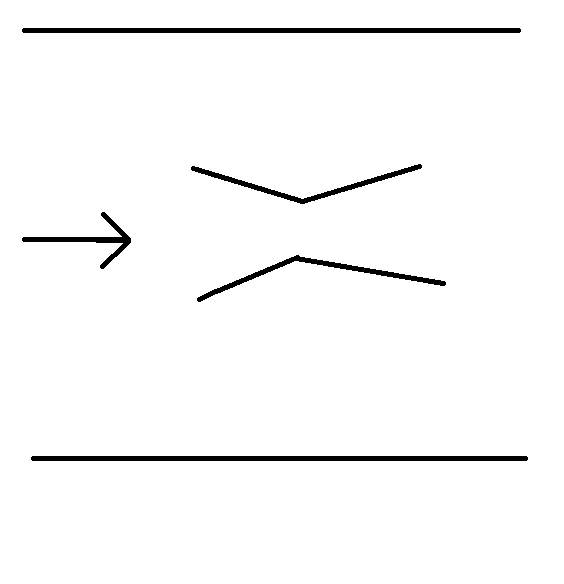

I know this is easy but i need to know the flow velocity through a pipe reducing in diameter inside a canal.

the

water velocity is 3m/s

water depth is 1.5 m

the pipe is at the bottom

inlet diameter 0.9m

small reduced diameter 0.6m

outlet diameter = 0.8m

note: this is an open canal with velocity 3m/s

canal width is 6.096 m

At least tell me how this should be approached

the

water velocity is 3m/s

water depth is 1.5 m

the pipe is at the bottom

inlet diameter 0.9m

small reduced diameter 0.6m

outlet diameter = 0.8m

note: this is an open canal with velocity 3m/s

canal width is 6.096 m

At least tell me how this should be approached

Last edited: