- #1

gabrieldom

- 1

- 0

- TL;DR Summary

- I am looking for a linear actuator very short when it's folded, but very long when it's deployed.

Hello,

I am working on a mechanics project, on which I encounter a problem that I am sure others have faced before. I have tried to find answers here and there by typing keywords, but I can't find what I am looking for.

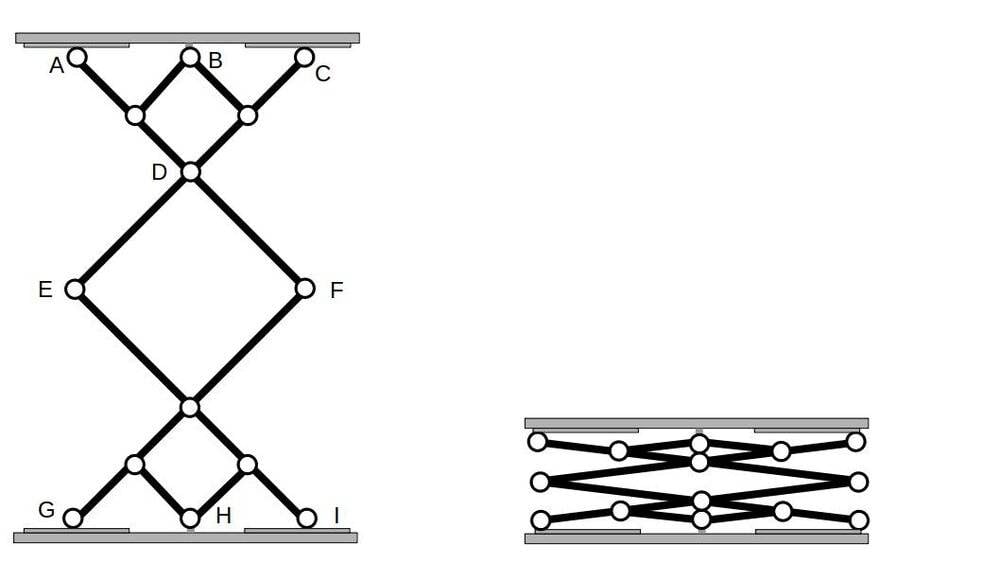

Here is the context: Two horizontal plates are separated by a mechanical system of articulated bars (a double scissor, like a laboratory scissor jack or like an aerial work platform). The bottom plate does not move, while the second can move vertically.

The top plate needs to be able to lift 10 kg to 50 cm high.

Initially, the mechanical system is completely folded between the two plates: bars are almost horizontal (2° angle between bars and the plates), so that the system is as thin as possible.

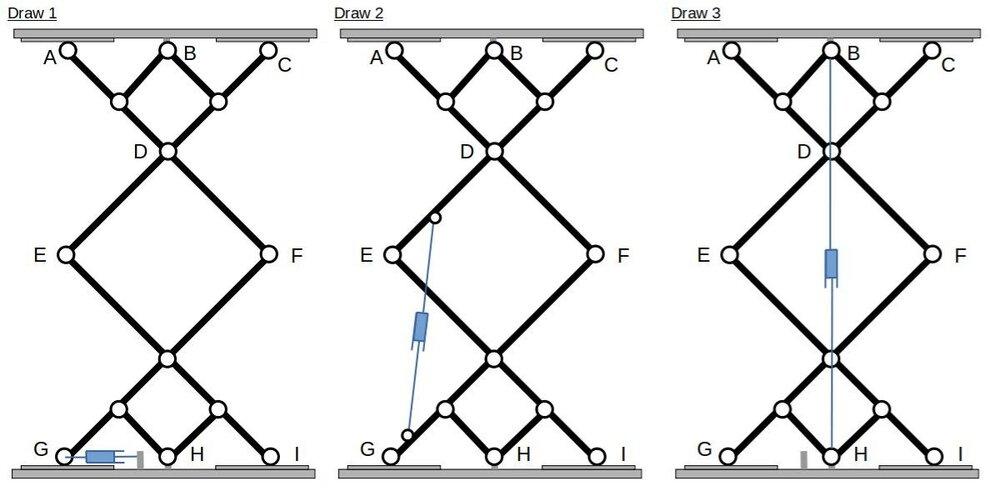

I thought installing a linear actuator to power the system, but I often come close to having the actuator almost horizontal when the system is folded (draw 1 and 2), therefore requiring a very strong force to lift the charge, due to a very important lever effect.

Ideally, I'd like to find a linear actuator that I could place vertically (so as to maximize its force) (draw 3), so with a great course (50 cm) but very small when folded (maximum is 5 cm) so that the plates can be as close as possible.

A telescopic cylinder with approximately 10 stages would be a good idea, but I am not familiar with hydraulic and pneumatic solutions, and I assume it would be much more complex to install and command.

Are there some solutions that exist to solve such kind of problem? I guess I am not the first to face this issue.

Do not hesitate if it is not clear.

Thanks!

I am working on a mechanics project, on which I encounter a problem that I am sure others have faced before. I have tried to find answers here and there by typing keywords, but I can't find what I am looking for.

Here is the context: Two horizontal plates are separated by a mechanical system of articulated bars (a double scissor, like a laboratory scissor jack or like an aerial work platform). The bottom plate does not move, while the second can move vertically.

The top plate needs to be able to lift 10 kg to 50 cm high.

Initially, the mechanical system is completely folded between the two plates: bars are almost horizontal (2° angle between bars and the plates), so that the system is as thin as possible.

I thought installing a linear actuator to power the system, but I often come close to having the actuator almost horizontal when the system is folded (draw 1 and 2), therefore requiring a very strong force to lift the charge, due to a very important lever effect.

Ideally, I'd like to find a linear actuator that I could place vertically (so as to maximize its force) (draw 3), so with a great course (50 cm) but very small when folded (maximum is 5 cm) so that the plates can be as close as possible.

A telescopic cylinder with approximately 10 stages would be a good idea, but I am not familiar with hydraulic and pneumatic solutions, and I assume it would be much more complex to install and command.

Are there some solutions that exist to solve such kind of problem? I guess I am not the first to face this issue.

Do not hesitate if it is not clear.

Thanks!