- #1

freddie_mclair

- 43

- 2

- TL;DR Summary

- After being a beam is bent, due to the springback effect, the resulting bent radius is larger than the bending radius. How can I estimate the residual stress that remains in the beam after an elasto-plastic loading/bending?

Hello everyone, I hope you can give me hand with what I will present.

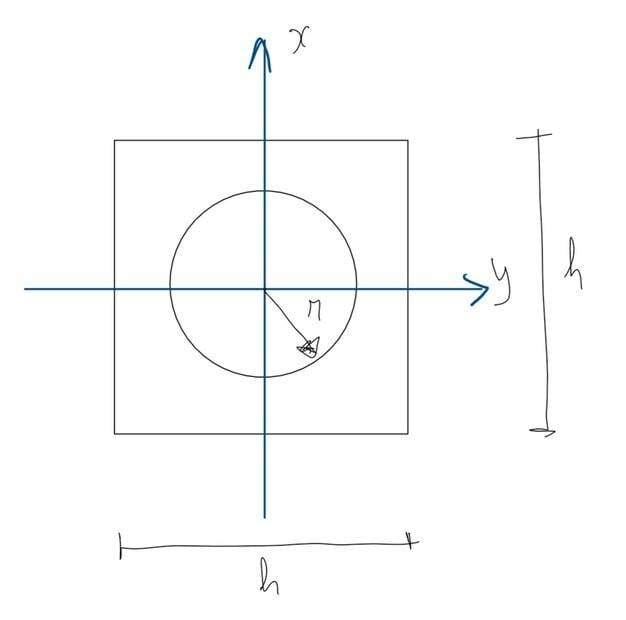

I have a beam with cross-section shown below.

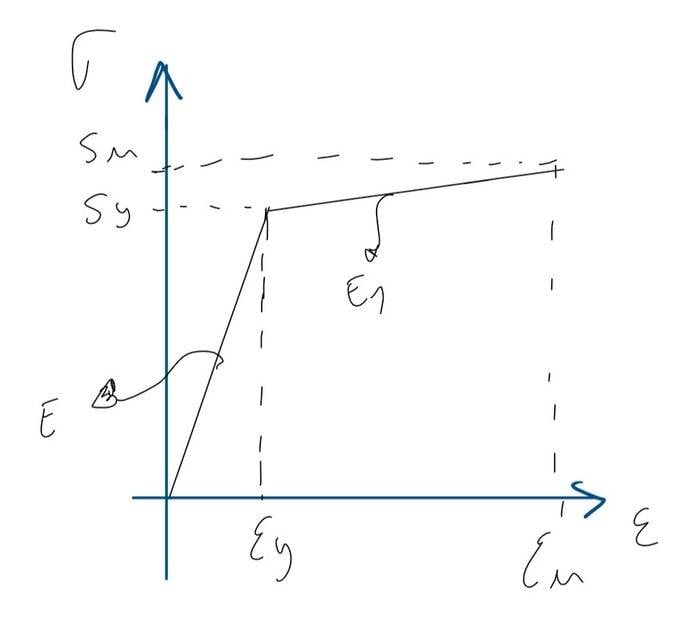

I considered a simple linear hardening model for predicting the stress and strain developed by bending the beam on the radius ##R_0## around the y-axis, where:

The strain, ##\varepsilon_L(x)##, can be defined as:

##\varepsilon_L(x) = \frac{x}{R_0}##

And the stress, ##\sigma_L(x)##, developed in the beam due to the loading by bending is:

##\sigma_L(x) = \begin{cases}

\frac{x}{R_0} \cdot E \mbox{, if } x \leq \varepsilon_y \cdot R_0\\

\sigma_L(x) = S_y+(\frac{x}{R_0}-\varepsilon_y)\cdot E_1\mbox{, if } x \gt \varepsilon_y \cdot R_0

\end{cases}##

Where and ##\varepsilon_y = \frac{S_y}{E}##, ##S_y## is the yield strength and ##E## the Young's Modulus.

##E_1## is the tangent modulus which is defined as shown in the picture below.

I also know that, due to the springback effect, the relationship between the bending radius ##R_0## and the resulting radius ##R_r## is given by:

##\frac{1}{R_0} - \frac{1}{R_r} = \frac{M_b}{EJ}##

Where ##M_b## is the bending moment and ##J## the moment of inertia (in this case ##J=\frac{h^4}{12}-\pi \frac{r^4}{4}##).

The bending moment can be estimated by:

##M_b=2\int_0^{h/2} \sigma_L(x) b(x) x dx##

Where ##b(x)\cdot x## is the cross-sectional area of the beam and ##b(x)## is defined by:

##b(x) = \begin{cases}

h-2\sqrt{r^2-x^2} \mbox{, if } x \leq r\\

h \mbox{, if } x \gt r

\end{cases}##

Now, with all this at hand, how can I estimate the residual stress on the beam after bending, i.e., after unloading the beam?

Thanks in advance!

I have a beam with cross-section shown below.

I considered a simple linear hardening model for predicting the stress and strain developed by bending the beam on the radius ##R_0## around the y-axis, where:

The strain, ##\varepsilon_L(x)##, can be defined as:

##\varepsilon_L(x) = \frac{x}{R_0}##

And the stress, ##\sigma_L(x)##, developed in the beam due to the loading by bending is:

##\sigma_L(x) = \begin{cases}

\frac{x}{R_0} \cdot E \mbox{, if } x \leq \varepsilon_y \cdot R_0\\

\sigma_L(x) = S_y+(\frac{x}{R_0}-\varepsilon_y)\cdot E_1\mbox{, if } x \gt \varepsilon_y \cdot R_0

\end{cases}##

Where and ##\varepsilon_y = \frac{S_y}{E}##, ##S_y## is the yield strength and ##E## the Young's Modulus.

##E_1## is the tangent modulus which is defined as shown in the picture below.

I also know that, due to the springback effect, the relationship between the bending radius ##R_0## and the resulting radius ##R_r## is given by:

##\frac{1}{R_0} - \frac{1}{R_r} = \frac{M_b}{EJ}##

Where ##M_b## is the bending moment and ##J## the moment of inertia (in this case ##J=\frac{h^4}{12}-\pi \frac{r^4}{4}##).

The bending moment can be estimated by:

##M_b=2\int_0^{h/2} \sigma_L(x) b(x) x dx##

Where ##b(x)\cdot x## is the cross-sectional area of the beam and ##b(x)## is defined by:

##b(x) = \begin{cases}

h-2\sqrt{r^2-x^2} \mbox{, if } x \leq r\\

h \mbox{, if } x \gt r

\end{cases}##

Now, with all this at hand, how can I estimate the residual stress on the beam after bending, i.e., after unloading the beam?

Thanks in advance!