- #1

davidfam

- 4

- 0

Hi all,

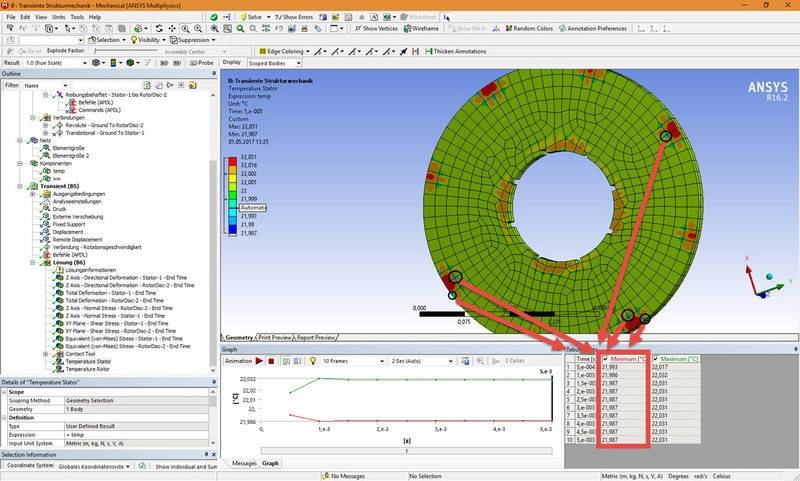

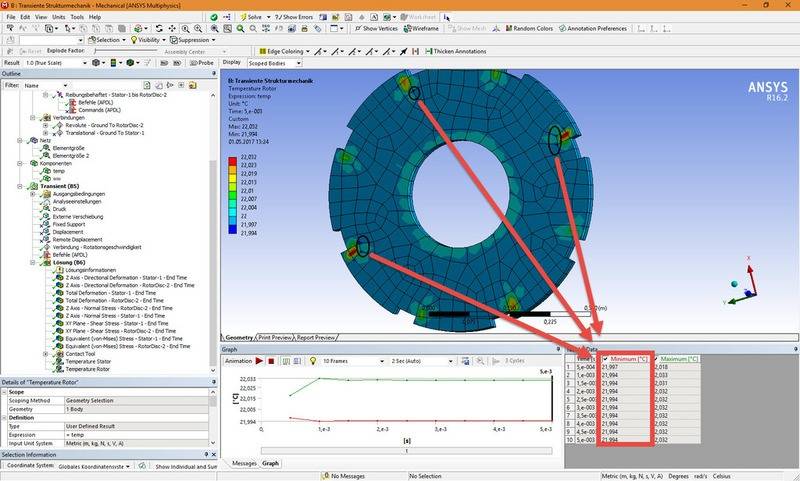

I'm currently working on my bachelor's thesis in mechanical engineering. I must simulate a brake model, which consist of 1 rotor and 1 stator. The rotor rotate around z-axis and the stator move along z-axis. When pressure is on stator placed. The stator and rotor will be pressed together.

i used Coupled Thermal-structural analysis in ANSYS Workbench with solid226, but the result seemed to be not so good since the min Temperature, which appear on knots near max Temperatur of both rotor and stator is cooler than reference Temperatur (22°C) and the Total Deformation of rotor is relatively large.

I tried to reduce Net size and timestep but without success.

Is there something wrong with my simulation? Can someone please help me. Thank you and sorry for my bad in english

I'm currently working on my bachelor's thesis in mechanical engineering. I must simulate a brake model, which consist of 1 rotor and 1 stator. The rotor rotate around z-axis and the stator move along z-axis. When pressure is on stator placed. The stator and rotor will be pressed together.

i used Coupled Thermal-structural analysis in ANSYS Workbench with solid226, but the result seemed to be not so good since the min Temperature, which appear on knots near max Temperatur of both rotor and stator is cooler than reference Temperatur (22°C) and the Total Deformation of rotor is relatively large.

I tried to reduce Net size and timestep but without success.

Is there something wrong with my simulation? Can someone please help me. Thank you and sorry for my bad in english