- #1

mohamedibr752

- 1

- 0

Greetings to all,

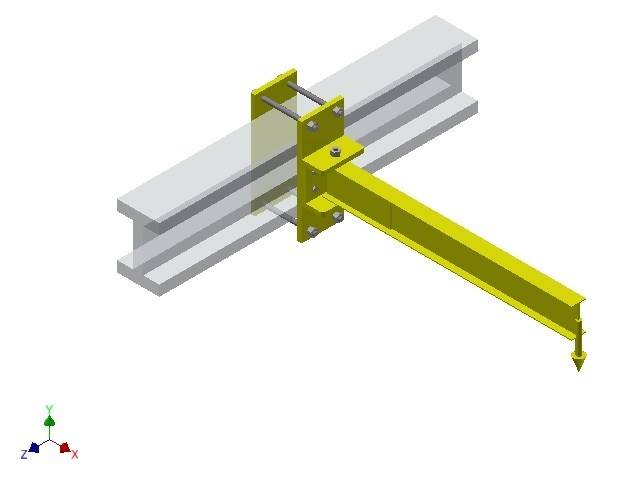

I am doing FEA analysis of a jib crane. I am using Autodesk Inventor.

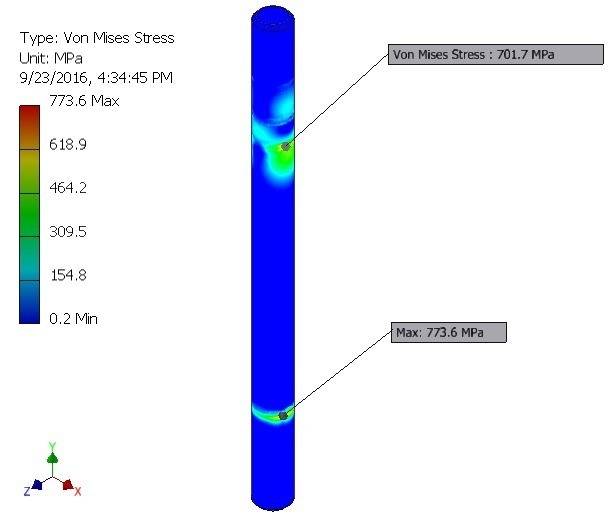

The results show that the max Von Mises stress in the support pin is 773 MPa. This value exceeds the yield strength of the Carbon Steel. Does this mean that the Pin will fail under load ?

I am doing FEA analysis of a jib crane. I am using Autodesk Inventor.

The results show that the max Von Mises stress in the support pin is 773 MPa. This value exceeds the yield strength of the Carbon Steel. Does this mean that the Pin will fail under load ?