- #1

perky416

- 16

- 0

Hi guys,

Here is my problem / task: I have a 232 bar pressure cylinder (not sue what material it is made from) with a brass fill valve at one end. I am trying to design a new shorter valve so that it takes up less space inside the cylinder, and thus increasing the capacity.

How would I calculate the minimum amount of threads I need to use before the pressure causes the thread to strip and the fitting comes flying out the end of the cylinder?

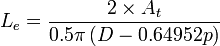

The original fitting has a thread engagement length of 10mm or 0.393 inches and uses an M25 x 1.0mm pitch thread. I have tried to use the following formula however it gives me an answer of 0.92904 inch / 23.59mm which is over twice the amount of the original fitting.

I understand that the first 6 threads take all the load, but If i use a stronger material for the fitting, say 303 stainless steel, can I get away with less threads?

I am trying to get the thread engagement length down to 5mm however I just don't know how to calculate it.

Regards

Here is my problem / task: I have a 232 bar pressure cylinder (not sue what material it is made from) with a brass fill valve at one end. I am trying to design a new shorter valve so that it takes up less space inside the cylinder, and thus increasing the capacity.

How would I calculate the minimum amount of threads I need to use before the pressure causes the thread to strip and the fitting comes flying out the end of the cylinder?

The original fitting has a thread engagement length of 10mm or 0.393 inches and uses an M25 x 1.0mm pitch thread. I have tried to use the following formula however it gives me an answer of 0.92904 inch / 23.59mm which is over twice the amount of the original fitting.

I understand that the first 6 threads take all the load, but If i use a stronger material for the fitting, say 303 stainless steel, can I get away with less threads?

I am trying to get the thread engagement length down to 5mm however I just don't know how to calculate it.

Regards