- #1

E.T.A.

- 7

- 0

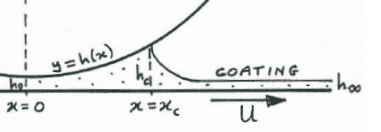

Basically, I'm modelling the flow of a "coating" process -- a fluid flow between a flat moving plane and a stationary cylinder, 2D, cartesian coordinates. Subscript 0 is the at the minimum height b/w the plane and the cylinder, and subscript c is at the point at which the flow leaves the moving plane-cylinder system and into the infinite-length "coating" mechanism. Diagram below:

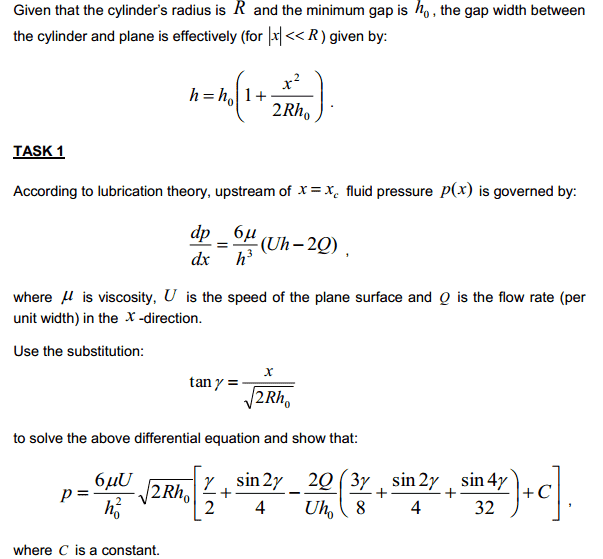

and the governing equations:

so, here's where I'm at:

Thanks!

and the governing equations:

so, here's where I'm at:

- I don't really get the need for the substitution (or is it some dimensionless parameter?). It feels pretty arbitrary right now and it's frustrating.

- I have subbed in the value for h into the eq. for dp/dx, and then attempted to solve that ODE via direct integration (?), which yields something pretty nasty. And, unfortunately, I'm not quite getting at which stage the given substitution's meant to happen (or -again- why), and quite where the sins are coming from.

Thanks!