- #1

PhysicsTest

- 238

- 26

- TL;DR Summary

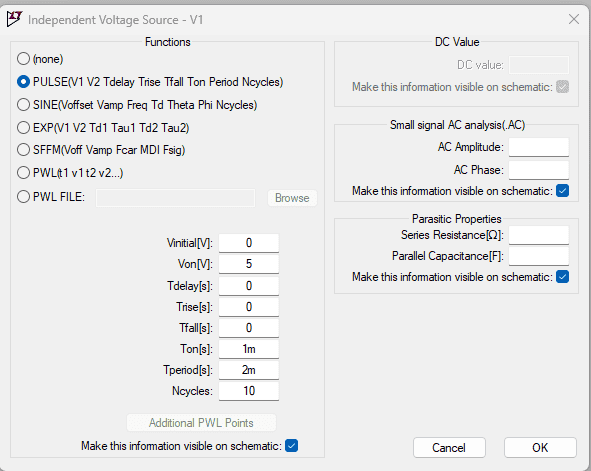

- How do i sweep pwm in ltspice from 0% to 100% duty

How do i simulate the PWM signal with duty from 0% to 100% in Ltspice.

I can generate a pwm signal with single duty.

I can generate a pwm signal with single duty.