Discussion Overview

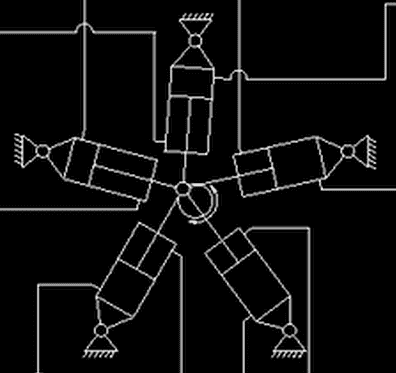

The discussion revolves around calculating the input torque required for a radial cylinder arrangement in a mechanical system, specifically focusing on the dynamics of a radial piston setup. Participants explore various methods for determining torque, including kinematic analysis and the effects of geometry on torque calculations.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

- One participant seeks assistance in calculating the input torque for a radial cylinder arrangement and shares a Google Sheet for collaborative calculations.

- Another suggests starting with the force on one piston due to pressure and calculating the torque about the crank axis, considering the contributions from other cylinders.

- Concerns are raised about calculating torque at various angles, with one participant expressing difficulty in understanding the necessary calculations beyond specific angles.

- A participant explains that torque is proportional to the sine of the angle between the connecting rod and the crank throw, detailing the relationship between piston force and angles involved.

- There is mention of the potential for piston seizure if the angle between the wrist pin and connecting rod becomes too steep, highlighting the importance of lubrication.

- One participant emphasizes the kinematic nature of the problem, suggesting that understanding the kinematics of a slider-crank system is crucial for analysis.

- Another participant warns about the inertia reaction torque that may arise from the moving mass of the hydraulic cylinders, particularly at higher speeds.

- Clarifications are made regarding the configuration of the cylinders, with one participant explaining the differences between their setup and traditional radial piston motors.

- There is a discussion about the complexity of determining final torque due to the arrangement of the cylinders and their pivoting nature.

- One participant proposes that determining torque could be simplified to a summation of forces from torque arms, while another questions the implications of shifting geometry during operation.

Areas of Agreement / Disagreement

The discussion contains multiple competing views on the best approach to calculate torque, and participants express varying levels of understanding and confidence in the calculations. There is no consensus on a single method or solution.

Contextual Notes

Participants highlight the complexity of the system due to the arrangement of cylinders and the potential for varying angles during operation, which may affect torque calculations. The discussion also touches on the limitations of each participant's understanding and the need for further exploration of kinematic principles.

Who May Find This Useful

Individuals interested in mechanical engineering, particularly those working with radial piston systems or seeking to understand torque calculations in dynamic systems.