Discussion Overview

The discussion revolves around calculating the static frictional force of nylon bushings in a hinge mechanism. Participants explore various methods and formulas to determine friction, including the implications of their experimental setup and the challenges associated with measuring friction in mechanical systems.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

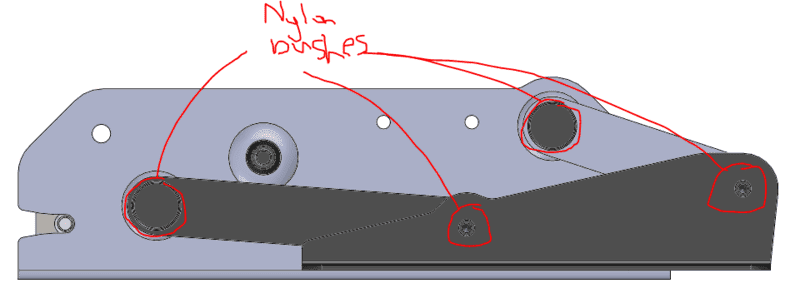

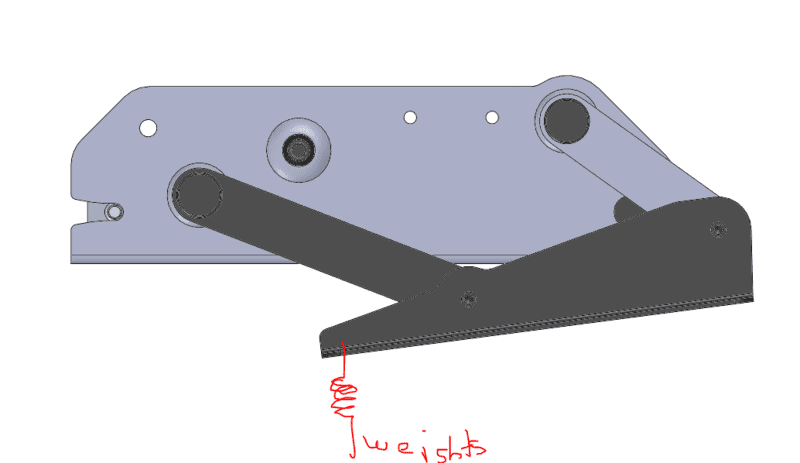

- One participant proposes using a hook to add weights until the hinge moves, suggesting that the weight multiplied by gravity could yield the static frictional force.

- Another participant corrects the first by stating that the product should be mass times gravity, emphasizing the need for clarity on the intended measurement.

- A participant questions the applicability of the formula Fs = μsN in this context, noting that it may not accurately reflect the friction at specific locations within the system.

- Concerns are raised about the variability in friction measurements due to material wear and manufacturing differences in the hinges.

- One participant expresses interest in determining the frictional force at individual pin joints, suggesting that a different experimental approach may be necessary for that purpose.

- Another participant introduces an equation for friction moment in bearings and references Petroff's equation for plain bearings, indicating alternative methods for estimating frictional forces.

Areas of Agreement / Disagreement

Participants do not reach a consensus on the best method to measure static frictional force or the applicability of certain formulas. Multiple competing views on the experimental approach and the interpretation of results remain evident throughout the discussion.

Contextual Notes

Participants highlight limitations in their experimental designs, including the challenge of isolating friction at specific joints versus measuring overall system friction. There is also uncertainty regarding the definition of normal force in the context of the proposed calculations.

Who May Find This Useful

Individuals interested in mechanical engineering, materials science, or experimental physics may find the discussion relevant, particularly those focused on friction measurements in mechanical systems.