Jesper Hellmann

- 2

- 0

Hi All

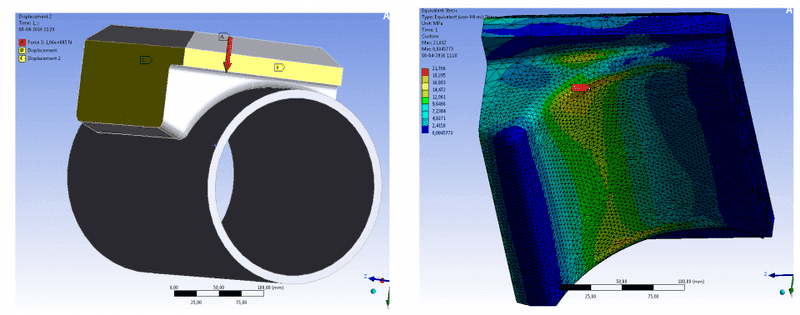

I am trying to validate a nylon (PA6 Guss) clamp which has a load of 166kN on a steel tube. I am only interested in validating the clamp.

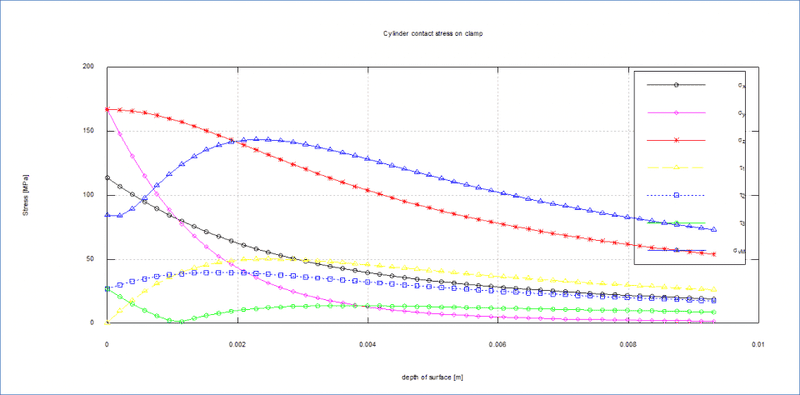

My analytical (MatLab-Octave) calculations give me a peak Von Misses stress of about 145MPa

When comparing to FEM in ANSYS I only get about 30MPa

Can someone shed light on why there is such a big difference?

-Jesper Hemmlann

M.Sc. Applied Mechanics

I am trying to validate a nylon (PA6 Guss) clamp which has a load of 166kN on a steel tube. I am only interested in validating the clamp.

My analytical (MatLab-Octave) calculations give me a peak Von Misses stress of about 145MPa

When comparing to FEM in ANSYS I only get about 30MPa

Can someone shed light on why there is such a big difference?

-Jesper Hemmlann

M.Sc. Applied Mechanics