Shahil

- 115

- 21

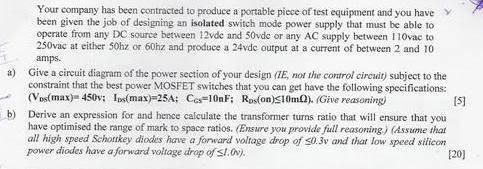

Hey guys ... I have inserted a picture of the question as it was easier to scan than to re-write :P It's based on Switching Mode Power Supplies.

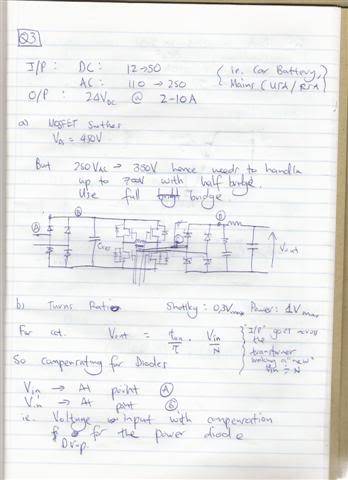

Check the picture or the upload on photobucket http://i91.photobucket.com/albums/k320/shahilj/Q3.jpg" ... It is basically a full bridge config that is required. What got me was that the supply ranges from 220Vac down to 12Vdc BUT the o/p is 12Vdc ... I got a bit confused as to what config to use.

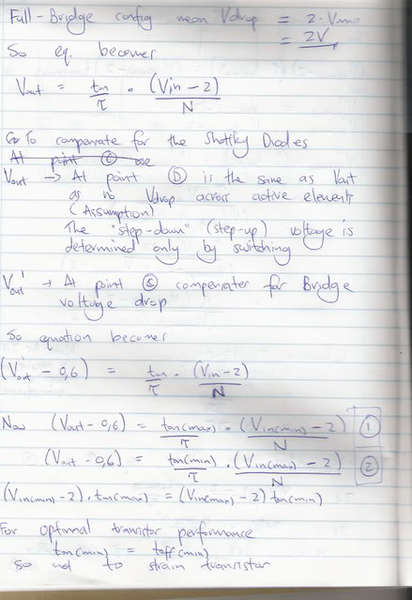

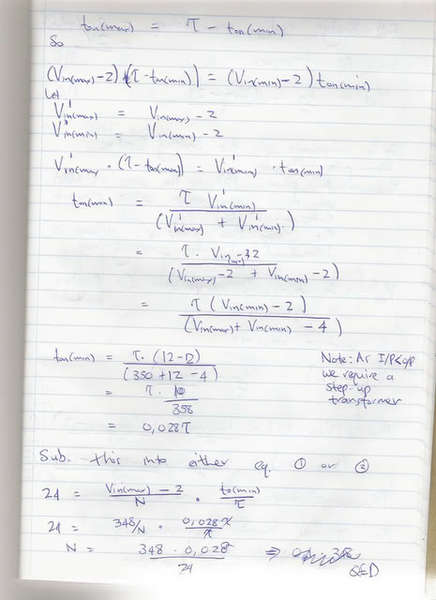

All equations are to be derived from first principles as such.

Heres the 3 links first ... http://i91.photobucket.com/albums/k320/shahilj/elec3ans1.jpg"

I kinda need someone to at least just check the work .. coz it is worth a lot of marks (25 out of a 100 mark paper) and I really need to know if my method is indeed right!

Thanks so much!

Homework Statement

Check the picture or the upload on photobucket http://i91.photobucket.com/albums/k320/shahilj/Q3.jpg" ... It is basically a full bridge config that is required. What got me was that the supply ranges from 220Vac down to 12Vdc BUT the o/p is 12Vdc ... I got a bit confused as to what config to use.

Homework Equations

All equations are to be derived from first principles as such.

The Attempt at a Solution

Heres the 3 links first ... http://i91.photobucket.com/albums/k320/shahilj/elec3ans1.jpg"

I kinda need someone to at least just check the work .. coz it is worth a lot of marks (25 out of a 100 mark paper) and I really need to know if my method is indeed right!

Thanks so much!

Last edited by a moderator: