- #1

connor67

- 3

- 0

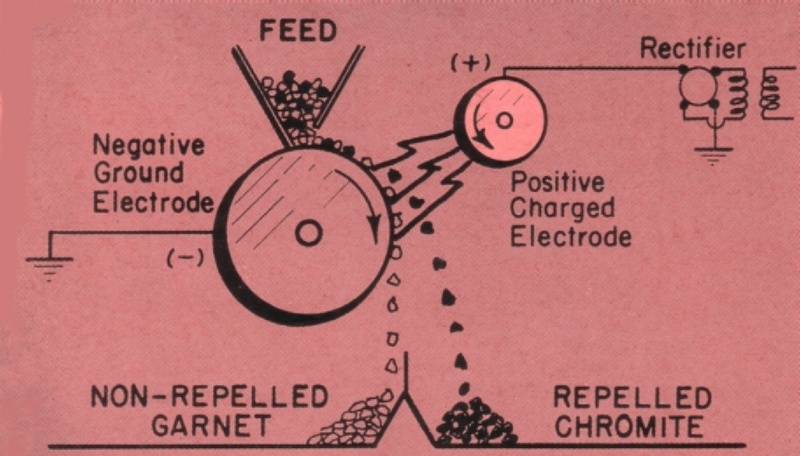

howdy, i am building an electrostatic seperator for plant material. the two materials i am trying to separate have a negative charge but one responds a lot more to positve charges so i feel there will still be sufficient seperation. i have the general plan for it done, i just had a few questions in regard to the rectifier, and if anybody had any input with the other aspects it would also be greatly apreciated. So now let me get into the plan. i attached a diagram to give you all an idea of what i am talking about. i plan on running a 220v cord to a junction box. from there i will have three connections, one to each motor and then one to the rectifier. then from the rectifier it will run to the positive electrode. attached to the motors will be the electrodes, the negative charge rotating clockwise and the positive rotating counter-clockwise. each electrode is going to be made of aluminum. the negative having a diameter of 6 inches and the positive a diameter of 12 inches. each also will have a depth of 12 inches. i feel this is the max size to go with still keeping a sufficient charge on the positive electrode. then the negative will be grounded to the steel frame. so to my questions, i was thinking of using a 35a 400v bridge rectifier and was wondering if that would be the appropriate one. also would it be fine to run just a positive from the junction box to the rectifier then the the electrode without a ground on that side? the only ground for the electrodes would be the one on the negative charge side. if i do need one between the rectifier and positive electrode, what would be the best way of placing it there? also do you all feel aluminum would be the best material to use for the electrodes? any help would be much appreciated.