Discussion Overview

The discussion revolves around finding a suitable drum or mechanism to attach to a gearbox motor for the purpose of lifting a 5kg box. Participants explore various options for drum designs, attachment methods, and considerations for effective operation, including the mechanics of string winding and load management.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

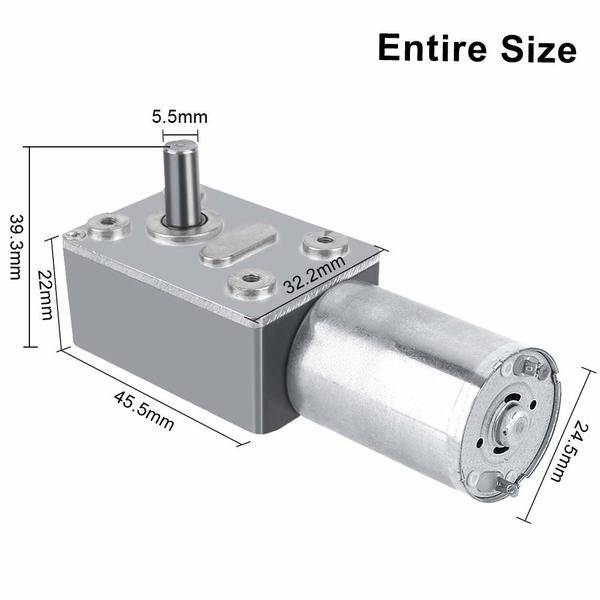

- One participant seeks advice on suitable drums for a motor shaft to lift a 5kg box and requests suggestions for attachment methods.

- Another participant suggests a specific drum from McMaster-Carr, recommending modifications for attachment to the motor shaft.

- There is confusion about how to attach the string to the pulley, with suggestions including using a slot in the shaft or tying the string around the drum with a constrictor knot.

- A participant emphasizes the importance of a guide mechanism to ensure even winding of the string or cable around the drum to prevent binding.

- Concerns are raised about the potential stress on the drum due to the weight being lifted, with calculations provided regarding the forces involved in winding the filament.

- One participant proposes adapting a fishing reel for the project, which is positively received by another participant.

- Clarification is sought regarding the stall torque of the motor and its implications for drum size.

Areas of Agreement / Disagreement

Participants express various ideas and suggestions, but there is no consensus on a single approach or solution. Multiple competing views on drum design and attachment methods remain unresolved.

Contextual Notes

Participants discuss the mechanical implications of the load on the drum, including potential stresses and the need for a robust design. There are also unresolved questions about the specifics of the motor's stall torque and its effect on the drum's dimensions.

Who May Find This Useful

Individuals interested in mechanical design, robotics, or DIY projects involving motors and lifting mechanisms may find this discussion relevant.