nezednemo

- 8

- 3

- TL;DR

- How to calculate deflection on a center supported plate with localized downward force applied.

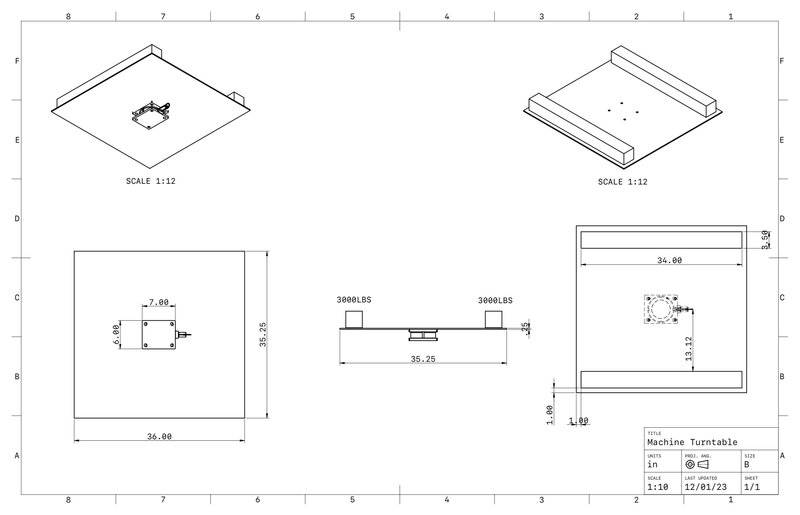

Good morning, I’m designing a turntable for a machine shop. The machine that rides on this platform weighs 6000 pounds and sits on (2) wood blocks (For ease of pickup with a fork lift). I’m trying to understand flexure rigidity and choose the right thickness of A36 steel plate.

I work closely with a metal supplier, so it is possible for me to get the chemistry on the plate, but I don’t know exactly what units to ask for.

The current plan is to use A36 ¼” Mild Steel diamond plate. I can increase the thickness of the plate to 5/16 or ⅜ if it significantly increases flexure rigidity.

I intend to reinforce the plate by welding flat bar around the edges (to reduce deflection) and adding ball transfer bearings around the perimeter of the rotational axis (to disperse weight transfer). A baseline of deflection of the plate without such supports will help me choose the right reinforcement strategy. My goal is to keep the plate as low as possible to the ground.

Thank you for looking over my project and let me know if there’s any way I can increase the clarity of my request.

I work closely with a metal supplier, so it is possible for me to get the chemistry on the plate, but I don’t know exactly what units to ask for.

The current plan is to use A36 ¼” Mild Steel diamond plate. I can increase the thickness of the plate to 5/16 or ⅜ if it significantly increases flexure rigidity.

I intend to reinforce the plate by welding flat bar around the edges (to reduce deflection) and adding ball transfer bearings around the perimeter of the rotational axis (to disperse weight transfer). A baseline of deflection of the plate without such supports will help me choose the right reinforcement strategy. My goal is to keep the plate as low as possible to the ground.

Thank you for looking over my project and let me know if there’s any way I can increase the clarity of my request.