Webbd050

- 35

- 4

Is it just a series of attracting magnets in a circle?

The internal flywheel bearings are going to be a problem. Rolling bearings fail very rapidly in a vacuum. Lead dust or silver powder has been used to lubricate ball bearings for rotating anodes in X-ray tubes.Webbd050 said:Basically what i have is a hermetically sealed vacuum chamber but i need to transmit torque via a shaft to and from a flywheel inside.

yes,Webbd050 said:Is it just a series of attracting magnets in a circle?

Webbd050 said:That great thanks mate :)

As our experience, it is not easy to do the magnetic coupling, by your own, because of the maching and manufacturing tools. anyway, there are so many supplier online offer http://www.greatmagtech.com/product_cat_list/Neodymium-Magnets-c21605.html and the shaft or steel shell. you can search it online.Webbd050 said:Basically what i have is a hermetically sealed vacuum chamber but i need to transmit torque via a shaft to and from a flywheel inside. The 2 ways i can see to do this is just having a seal on the shaft which might leak and cause a lot of friction or transmitting the torque through the wall of the chamber via a magnetic coupling but i don't fully understand how they work or whether they are available to buy. could i just construct my own with some neodymium magnet do you think? Thanks for the reply :)

the pictures are vivid and lively.Q_Goest said:You're correct, a magnetic coupling transmits torque by using magnets on both sides of some pressure boundary.

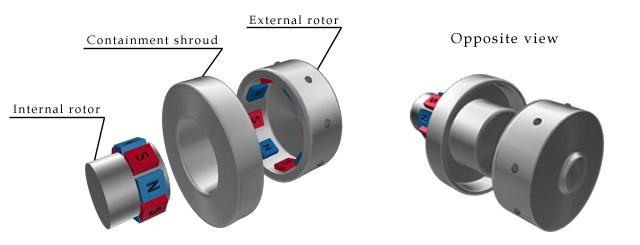

The magnets can either be set up around a cylinder:

Or around a flat disk:

Obviously there is a non-magnetic pressure boundary that will be placed between the two. The distance between the magnets will dictate how much torque you can transmit for any given application but if you're only transmitting through a wall that has a differential pressure of one atmosphere, you won't have any problems. I've seen them used in applications where the pressure is many hundreds of psi.

You can purchase them off the shelf so I wouldn't try and design your own. Just do a search on magnetic couplings and you'll find all sorts of suppliers.

You have reinvented the induction motor where a conductive rotor is dragged by a rotating magnetic field. You can achieve the same by using a three phase field winding rather than permanent magnets. With 3 phase AC you can better control the speed and do not need external moving parts.Darryl said:If you have two aluminium discs with magnets fitted to one of the discs on the fact, you rotate one, and the other will follow it, due to the eddy currents generated in the disc.

The energy released while braking still appears as heat in the conductive disc. That is because eddy currents induced in the disc release heat proportional to I2R. The advantage of eddy current braking is that there is no friction material to wear out or burn. The disc can be more efficiently air cooled if there are no hot friction pads insulating it from the air. Changes in disc surface due to contamination, water or changes in the metal are also largely eliminated.Darryl said:I have also seen this used for high speed disc breaking in fast cars, as you don't get friction heat, and the higher the speed (rate of change) the more effect happens.