StoyanNikolov

- 50

- 0

- TL;DR

- LC Induction heater with high Q factor

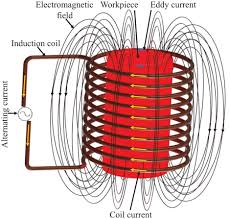

Consider Parallel LC Resonance Induction heater.

The material to be heated is from copper

(it has relative magnetic permeability 1 and does not change with different temperatures)

and is placed inside Inductor coil and there is Air gap between the coil perimeter and the material.

Like this one on the picture:

Source: https://www.semanticscholar.org/pap...Pant/a171ec4494599a22a7bde3ad92d24d56e43510d0

Source: https://www.semanticscholar.org/pap...Pant/a171ec4494599a22a7bde3ad92d24d56e43510d0

The shape of the material is Cylindrical.

Is it possible to design induction heater with high Q factor (above 100) when the copper cylindrical workpiece is inserted in the heating coil

(There is Air gap between coil and copper material)?

Perhaps with very high frequency? Thank you.

The material to be heated is from copper

(it has relative magnetic permeability 1 and does not change with different temperatures)

and is placed inside Inductor coil and there is Air gap between the coil perimeter and the material.

Like this one on the picture:

The shape of the material is Cylindrical.

Is it possible to design induction heater with high Q factor (above 100) when the copper cylindrical workpiece is inserted in the heating coil

(There is Air gap between coil and copper material)?

Perhaps with very high frequency? Thank you.