SUMMARY

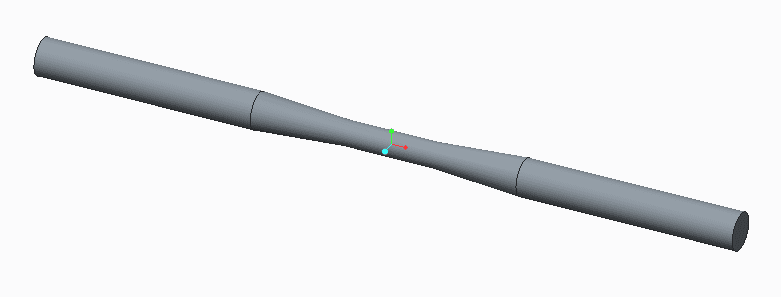

The discussion focuses on measuring the diameter of a curved part, highlighting the limitations of traditional vernier calipers for non-parallel surfaces. Various measurement methods are proposed, including the use of Coordinate Measurement Machines (CMM), optical profilometers, and point micrometers. A jig with laser distance sensors is suggested for accurate measurements along the curvature, especially for high-volume production. The feasibility of these methods depends on the production quantity and required accuracy.

PREREQUISITES

- Understanding of Coordinate Measurement Machines (CMM)

- Familiarity with optical profilometers

- Knowledge of laser distance sensor technology

- Experience with jig design for measurement applications

NEXT STEPS

- Research the specifications and capabilities of CMMs for curved part measurement

- Explore the use of optical profilometers for surface roughness and curvature measurement

- Investigate the design and implementation of jigs for laser distance sensors

- Learn about point micrometers and their application in measuring curved surfaces

USEFUL FOR

Manufacturing engineers, quality control inspectors, and anyone involved in the precision measurement of curved components in production settings.

I know there is some photographic method of measuring distances, however I would like to know is there no way of physically measuring the diameter along the curvature.

I know there is some photographic method of measuring distances, however I would like to know is there no way of physically measuring the diameter along the curvature.