mastermechanic

- 107

- 15

- TL;DR

- Measuring the total pressure of centrifugal compressor by measuring the static temperature and the blade velocity

Hello everyone,

Nowadays I am planning to redesign my centrifugal compressor which I designed for a subsystem in my graduation project. It's a 3D printed and brushless motor driven centrifugal compressor and its about a hand size. However, due to its relatively small size and relatively low RPM ( about 15,000 RPM) it didn't provide enough pressure. In fact, I knew that it won't work because I designed it to reach 1.01 bar :) because I was limited by the material, motor and the budget. I just wanted to give it a try.

Anyway, now I want to scale it in order to reach about a 2 bar. Without doing any changes on the blade profile or casing (maybe I do because there may be choking) I will increase the motor speed with a gearbox and also scale up the model to increase the tangential velocity of the blade tip.

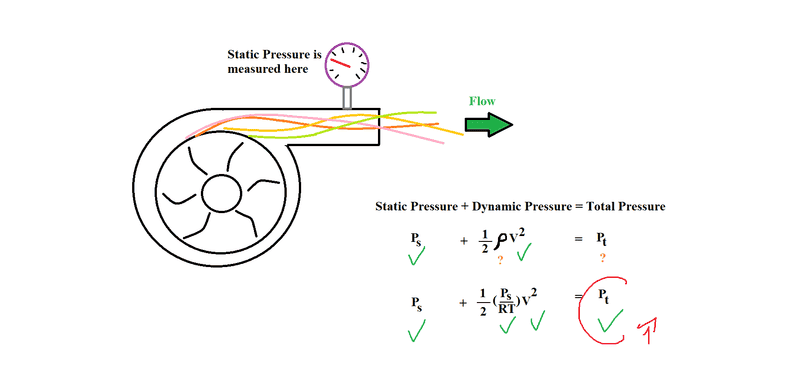

This time, I want to measure the values in order to validate my calculations. Therefore, I need to know total pressure of the blowed air. I am going to buy an absolute pressure manometer for gases and place it to the end of the compressor. This will measure the static pressure of the air.

I will approximate the air velocity from the tangential velocity of the blade (because I will be able to measure motor speed with a tachometer).

But since the density in the dynamic pressure is coupled with the pressure and temperature. I am planning to calculate density from ideal gas law. Assuming the temperature increase is not significant, taking the room temperature and static pressure measured in the compressor the density and eventually total pressure can be calculated.

So my question is that is this process correct? Would I get reasonable values? Here, the total pressure will be a function of the static pressure measured and temperature (approximated).

Thank you in advance,

Nowadays I am planning to redesign my centrifugal compressor which I designed for a subsystem in my graduation project. It's a 3D printed and brushless motor driven centrifugal compressor and its about a hand size. However, due to its relatively small size and relatively low RPM ( about 15,000 RPM) it didn't provide enough pressure. In fact, I knew that it won't work because I designed it to reach 1.01 bar :) because I was limited by the material, motor and the budget. I just wanted to give it a try.

Anyway, now I want to scale it in order to reach about a 2 bar. Without doing any changes on the blade profile or casing (maybe I do because there may be choking) I will increase the motor speed with a gearbox and also scale up the model to increase the tangential velocity of the blade tip.

This time, I want to measure the values in order to validate my calculations. Therefore, I need to know total pressure of the blowed air. I am going to buy an absolute pressure manometer for gases and place it to the end of the compressor. This will measure the static pressure of the air.

I will approximate the air velocity from the tangential velocity of the blade (because I will be able to measure motor speed with a tachometer).

But since the density in the dynamic pressure is coupled with the pressure and temperature. I am planning to calculate density from ideal gas law. Assuming the temperature increase is not significant, taking the room temperature and static pressure measured in the compressor the density and eventually total pressure can be calculated.

So my question is that is this process correct? Would I get reasonable values? Here, the total pressure will be a function of the static pressure measured and temperature (approximated).

Thank you in advance,