khodournajem

- 2

- 0

- Homework Statement

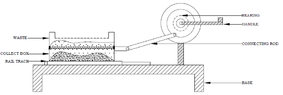

- I'm making a small project (horizontal sieving machine)

i will use the crank slide mechanism , the doctor want from me to calculate the input power of the dc motor and the output power to calculate the efficiency of the system.

so i test the maximum load which is 10 kg equally distributed on a frame of 6 bearings of friction coefficient 0.3,

the minimum displacement of the net frame to begin sieving is 5 cm per 1 second which is 0.05/s meters,

so the crank radius will be 2.5 cm (0.025) that gives a 60 rpm and i am using a 10 cm connecting rode. so this is my critical issue.

is i'm thinking right ?

how can i calculate the power?

do i have to calculate the force of the crank ?

how can i calculate the output power if my result is correct.

please help

- Relevant Equations

- 𝐹=μN

𝐹𝑐𝑟𝑎𝑛𝑘=ma

𝜏=F×d

P=τ×w

r = 2.5

l=10 cm

angle = 0 (maximum connecting rode elongation)

w = 0.5 (30 rpm)

n=10/2.5 = 4

so the acceleration is 1.5×0.5×0.5(1 + 1/4 ) = 0.4 m/s

friction force = 10*9.81*0.3 = 29.4 Newton.

Crank force is the mass of the object into acceleration.

So crank force = 10 × 0.4 = 4 Newton

Therefore total force will be: 29.4 + 4 =33.4 Newton.

Torque is the total force into the distance.

So torque = 33.4 × 0.05 = 1.67 N.m.

Finally motor power is the torque into the angular speed in minute.

Power = 1.67 × 30 = 50 watts.here is a approx picture (in my project the motor and the connecting rode and the frame is horizontally placed)

l=10 cm

angle = 0 (maximum connecting rode elongation)

w = 0.5 (30 rpm)

n=10/2.5 = 4

so the acceleration is 1.5×0.5×0.5(1 + 1/4 ) = 0.4 m/s

friction force = 10*9.81*0.3 = 29.4 Newton.

Crank force is the mass of the object into acceleration.

So crank force = 10 × 0.4 = 4 Newton

Therefore total force will be: 29.4 + 4 =33.4 Newton.

Torque is the total force into the distance.

So torque = 33.4 × 0.05 = 1.67 N.m.

Finally motor power is the torque into the angular speed in minute.

Power = 1.67 × 30 = 50 watts.here is a approx picture (in my project the motor and the connecting rode and the frame is horizontally placed)