- #1

Martin Quevedo

- 5

- 1

Hi all distinguished members of this forum !

As my first post here I would like to open with a situation I have been struggling with

I have attached a simple diagram of my problem

I have 2 cylindrial N52 neodymium magnets axially aligned with each other with opposite poles facing each other.

in the middle of both magnets there is a HiperCo 50 metal

The idea is that the net force on each magnet is zero. That is, the force of repulsion between the magnets and the force of attraction between magnet and metal (hiperco alloy) cancel one another.

I will very much appreciate if someone can share some math that allows to calculate the thickness required on the hiperco metal to achieve Fa and Fr to cancel.

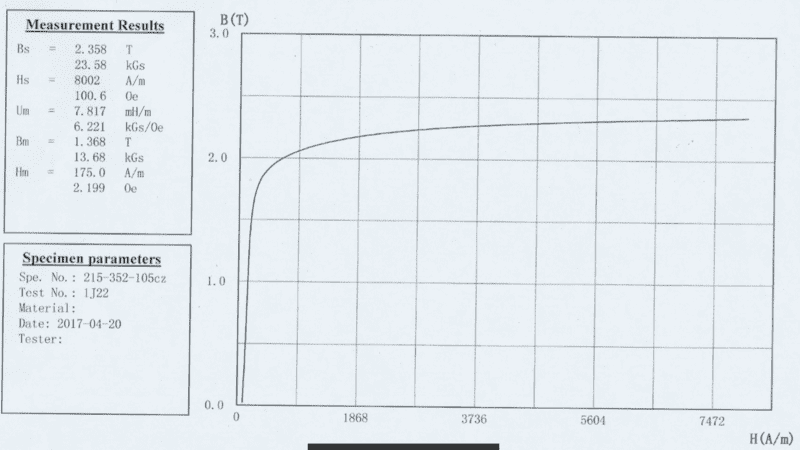

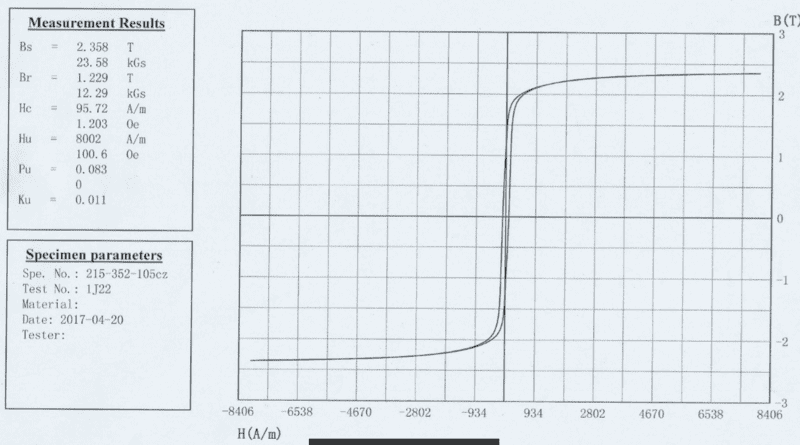

I have also attached BH graph of the hipeco alloy

best regards,

Martin

As my first post here I would like to open with a situation I have been struggling with

I have attached a simple diagram of my problem

I have 2 cylindrial N52 neodymium magnets axially aligned with each other with opposite poles facing each other.

in the middle of both magnets there is a HiperCo 50 metal

The idea is that the net force on each magnet is zero. That is, the force of repulsion between the magnets and the force of attraction between magnet and metal (hiperco alloy) cancel one another.

I will very much appreciate if someone can share some math that allows to calculate the thickness required on the hiperco metal to achieve Fa and Fr to cancel.

I have also attached BH graph of the hipeco alloy

best regards,

Martin