Discussion Overview

The discussion revolves around the design of a collet with a hexagonal inner profile and its ability to deform uniformly when clamping. Participants explore the number of slots required for effective clamping, the implications of slot placement, and the effects of collet design on performance, particularly in relation to machining processes.

Discussion Character

- Technical explanation

- Debate/contested

- Experimental/applied

Main Points Raised

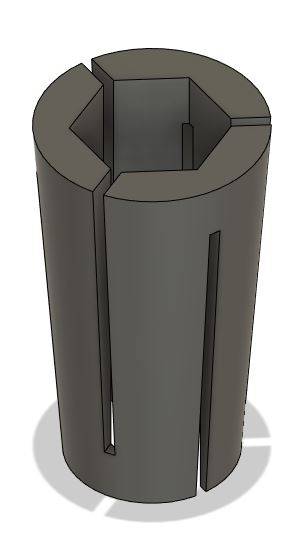

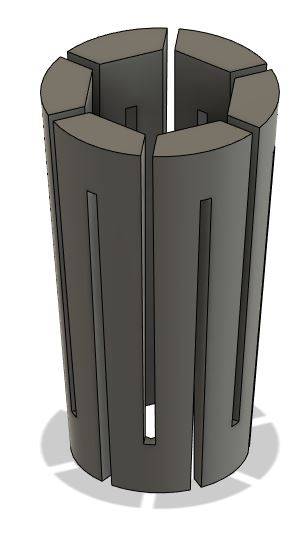

- Some participants propose that a collet with 6 slots is sufficient for uniform deformation, as it avoids slots in the flats of the hex, which are critical for alignment.

- Others argue that if the hexagon size differs from the collet, more slots may be necessary to accommodate greater dimensional changes.

- One participant mentions the importance of maintaining parallel walls during clamping to maximize surface contact area with the hex.

- There is a discussion on whether slitting should occur at both ends of the collet, with some suggesting that slitting at one end may lead to uneven clamping.

- Some participants highlight the differences between ER collets and 5C collets, noting that ER collets allow for a more uniform clamping range due to their design.

- Concerns are raised about the strength of three-jaw collets compared to hexagonal collets, particularly regarding the distribution of forces and the effectiveness of clamping.

- Participants discuss the potential for using different machining techniques, such as wire EDM or abrasive discs, to create slots after hardening the collet.

- There is mention of the need for a compromise in design based on specific requirements and the intended application of the collet.

Areas of Agreement / Disagreement

Participants express differing views on the optimal number of slots and their placement, indicating that multiple competing perspectives remain. The discussion does not reach a consensus on the best approach for collet design.

Contextual Notes

Participants note that the effectiveness of the collet design may depend on specific machining conditions, such as the size of the hex and the intended application. There are also unresolved considerations regarding the impact of slot placement on clamping performance.