- #1

DoctorLem

- 2

- 0

- TL;DR Summary

- I am installing a Thermal Mass in the center of our home. We are looking to figure out how much PEX pipe and what diameter for proper thermal transfer.

Hello friends!

We are installing a future provision for a Rocket Mass-type woodstove in our home.

This is a future project but realized that we could take advantage of the open area between the footing and finished floor by adding an insulated block of concrete with PEX pipes for Heating and Cooling Thermal Mass. The intention being to charge the Mass with heat from outside boiler, plate collectors, evac tube collectors, ext. Assuming water temp would be around 100ºF entering Mass. Summertime use would be for cooling with a buried loop system.

The Mass material will either be concrete or rammed earth, isolated from the stem walls and footing with 2" rigid foam, capped with stained concrete at finished floor level.

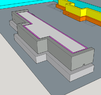

The volume measures around 22" high, throughout, 20ish' wide and between 3-6' deep, depending on where you measure in the "T" shaped foundation. This will be around 2.7 cubic yards of mass plus the top slab (the eventual fireplace will rest on the top slab).

The main questions being:

-What size PEX would be preferable?

-What amount of linear feet would I use to get maximum thermal transfer?

-What water velocity would I need to plan on achieving for water flow?

Thanks for any assistance in finding resources!

We are installing a future provision for a Rocket Mass-type woodstove in our home.

This is a future project but realized that we could take advantage of the open area between the footing and finished floor by adding an insulated block of concrete with PEX pipes for Heating and Cooling Thermal Mass. The intention being to charge the Mass with heat from outside boiler, plate collectors, evac tube collectors, ext. Assuming water temp would be around 100ºF entering Mass. Summertime use would be for cooling with a buried loop system.

The Mass material will either be concrete or rammed earth, isolated from the stem walls and footing with 2" rigid foam, capped with stained concrete at finished floor level.

The volume measures around 22" high, throughout, 20ish' wide and between 3-6' deep, depending on where you measure in the "T" shaped foundation. This will be around 2.7 cubic yards of mass plus the top slab (the eventual fireplace will rest on the top slab).

The main questions being:

-What size PEX would be preferable?

-What amount of linear feet would I use to get maximum thermal transfer?

-What water velocity would I need to plan on achieving for water flow?

Thanks for any assistance in finding resources!