- #1

dspdrew

- 4

- 0

Hi, I have been working on a formicarium (terrarium for ants) design for a while now, and have been battling a problem with what I think is corrosion of gypsum cement. This design has a hydration system that basically uses capillary action to wick water up a sponge and into gypsum cement (Hydrostone to be exact). What happens, is in just a matter of hours, the sponge or any other material litterally eats its way into the Hydrostone, and sometimes I actually find pin holes all the way through 1/4 inch of it.

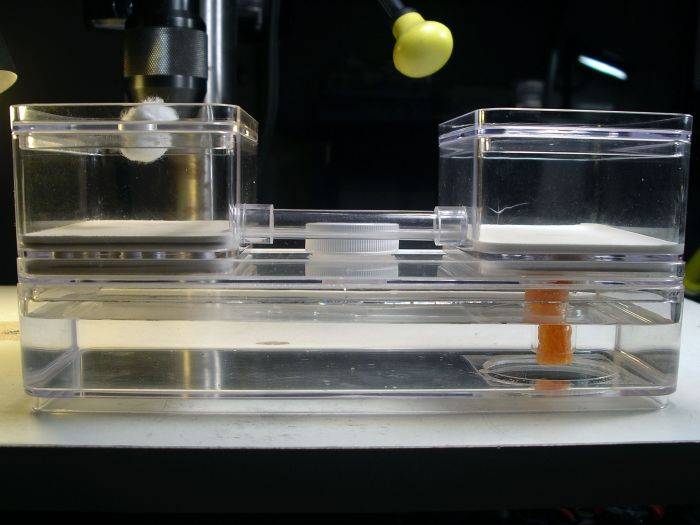

This is what this particular formicarium looks like. This is the one mostly affected by this problem.

This is what the top (floor of the top container) looks like after eight hours or so.

This is what the top (floor of the top container) looks like after eight hours or so.

This is the bottom of the top container (directly below the hole in the first picture). This is what actually sits on the sponge.

This is the bottom of the top container (directly below the hole in the first picture). This is what actually sits on the sponge.

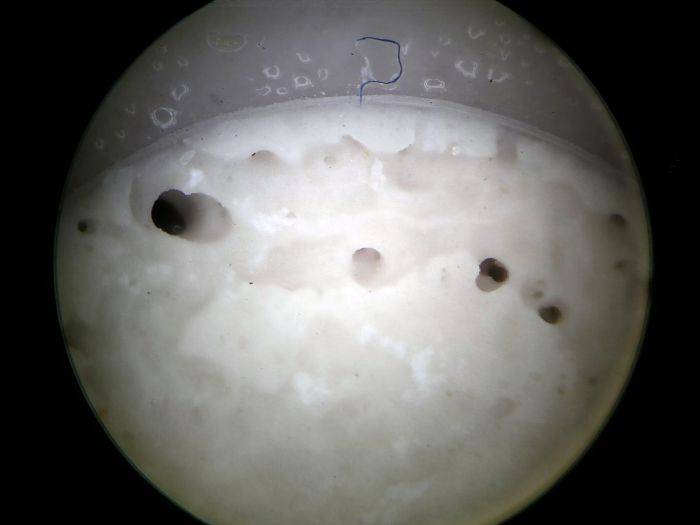

This is the bottom magnified.

This is the bottom magnified.

Hydrostone is made up of >95% Plaster of Paris, <5% Portland Cement, and <5% Crystalline Silica.

The MSDS can be found here: http://www.usg.com/content/dam/USG_...ydro-stone-gypsum-cement-msds-en-52140052.pdf

The water used is typical bottled water.

Quite a few people I know have suggested this could be a pH issue causing calcium to dissolve.

If anyone can tell me what might be happening here, and if there's a way to stop it, it would be much appreciated.

This is what this particular formicarium looks like. This is the one mostly affected by this problem.

Hydrostone is made up of >95% Plaster of Paris, <5% Portland Cement, and <5% Crystalline Silica.

The MSDS can be found here: http://www.usg.com/content/dam/USG_...ydro-stone-gypsum-cement-msds-en-52140052.pdf

The water used is typical bottled water.

Quite a few people I know have suggested this could be a pH issue causing calcium to dissolve.

If anyone can tell me what might be happening here, and if there's a way to stop it, it would be much appreciated.

Last edited: