cDuck28Z

- 2

- 0

Good evening,

First Post here on PhysicsForums! I'm building myself a 1939 Chevy HotRod and have encountered a slight problem with my build. I'm trying to find a wheel that will fit my project, but the problem is that they don't make it! There are numerous forums online with people both for and against wheel spacers, but I want to know the physics behind these little devices. The concept is simple: add a spacer between your wheel hub and the mounting surface of your wheel.

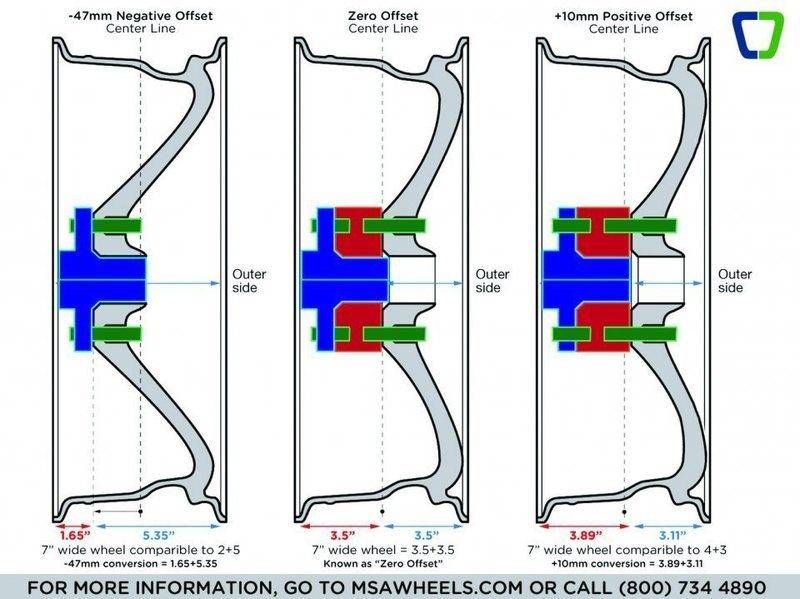

I'm trying to figure out if there is actually any difference in force on my lug studs (green) between having a -47mm offset or a 0 or +10mm offset. On one hand, I look at it an think 'Of course there's going to be more force, the wheel is so much further away from the hub'. On the other hand however, all of the forces of the vehicle, both while at rest and while driving, are located in the exact same location in all three scenarios. So would there actually be a difference?!

Please note, my diagram is off just a bit with regards to the lug studs. The holes are offset (see example image below) so there is more than enough metal to transfer the force of the vehicle.

PS. My hotrod will weigh an estimated 1400kg with aprox 850kg over the front wheels. Aprox 1.37m track (center point to center point of front tires) and 2.84m wheelbase.

First Post here on PhysicsForums! I'm building myself a 1939 Chevy HotRod and have encountered a slight problem with my build. I'm trying to find a wheel that will fit my project, but the problem is that they don't make it! There are numerous forums online with people both for and against wheel spacers, but I want to know the physics behind these little devices. The concept is simple: add a spacer between your wheel hub and the mounting surface of your wheel.

I'm trying to figure out if there is actually any difference in force on my lug studs (green) between having a -47mm offset or a 0 or +10mm offset. On one hand, I look at it an think 'Of course there's going to be more force, the wheel is so much further away from the hub'. On the other hand however, all of the forces of the vehicle, both while at rest and while driving, are located in the exact same location in all three scenarios. So would there actually be a difference?!

Please note, my diagram is off just a bit with regards to the lug studs. The holes are offset (see example image below) so there is more than enough metal to transfer the force of the vehicle.

PS. My hotrod will weigh an estimated 1400kg with aprox 850kg over the front wheels. Aprox 1.37m track (center point to center point of front tires) and 2.84m wheelbase.