- #1

Anachronist

Gold Member

- 117

- 47

- TL;DR Summary

- Need to know how to adjust drag coefficient from OpenFOAM calculation with wedge mesh.

(New thread following up to a conversation in another thread).

I'm using SimFlow 3.1 with OpenFOAM 5 on Linux to try to evaluate the drag coefficient of a water rocket body, constructed from a 2-liter Coke bottle with a conical nose, traveling through air at 77 m/s.

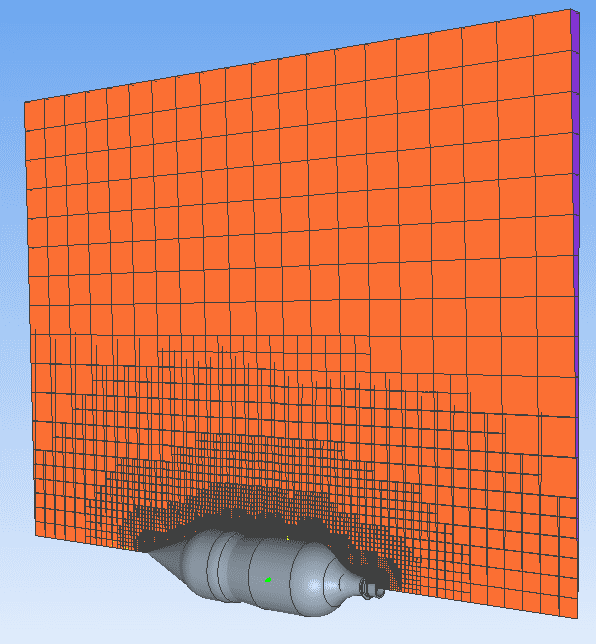

This should be a simple axisymmetric problem. So I created a wedge mesh, set it up for incompressible flow with RANS k-ω SST turbulence, force monitoring in the x direction. Here's a picture of my model with my wedge mesh:

I have a fair idea of what the drag coefficient should be: somewhere between 0.1 and 0.2. But OpenFoam reports orders of magnitude lower: 0.00058.

Why is this?

I'm a newbie when it comes to CFD. When I was taking college physics 35 years ago, I don't believe CFD even existed then; at least it wasn't taught. I chose SimFlow as an OpenFOAM front-end mostly to have a GUI and to shield me from drowning in the OpenFOAM documentation, which isn't written for newbies and assumes a high level of expertise already. SimFlow also has good tutorials on their website.

As far as I can tell from the OpenFOAM documentation, the wedge angle is 5 degrees by default, or 1/72 of a circle. Is there some adjustment I need to do, to account for this wedge size and the reference area? I'm using the circular area projected into the airflow as Aref and the overall length as Iref. Should I be using the projected area just inside the wedge, or the whole wetted area from nose to tail inside the wedge, and then multiply the result by 72 or something?

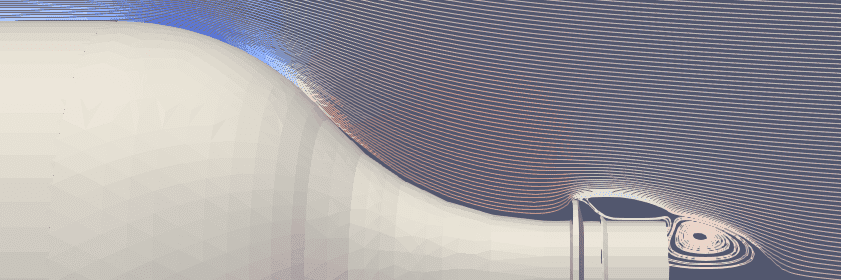

Another thing I don't understand is the absence of flow separation at the bottle taper. I'm pretty certain that a 2-liter soda bottle traveling at 77 m/s through air will have flow separation there. This is no airfoil! I've seen separation on small airfoils in actual wind tunnels at lower velocities than that. The separation at the nozzle collar and nozzle opening is expected, but I can't bring myself to believe that there's laminar flow over the bottle shoulder. Here's what I get:

This has been a long slogging learning curve so far. Not just for SimFlow, but for the FreeCAD software I had to learn to create my model. I'm happy that I got ANY result at all... but I am not believing what OpenFOAM is telling me. The drag coefficient is unrealistically low, and the flow lines look too smooth.

Does anyone have any advice on how to proceed?

I'm using SimFlow 3.1 with OpenFOAM 5 on Linux to try to evaluate the drag coefficient of a water rocket body, constructed from a 2-liter Coke bottle with a conical nose, traveling through air at 77 m/s.

This should be a simple axisymmetric problem. So I created a wedge mesh, set it up for incompressible flow with RANS k-ω SST turbulence, force monitoring in the x direction. Here's a picture of my model with my wedge mesh:

I have a fair idea of what the drag coefficient should be: somewhere between 0.1 and 0.2. But OpenFoam reports orders of magnitude lower: 0.00058.

Why is this?

I'm a newbie when it comes to CFD. When I was taking college physics 35 years ago, I don't believe CFD even existed then; at least it wasn't taught. I chose SimFlow as an OpenFOAM front-end mostly to have a GUI and to shield me from drowning in the OpenFOAM documentation, which isn't written for newbies and assumes a high level of expertise already. SimFlow also has good tutorials on their website.

As far as I can tell from the OpenFOAM documentation, the wedge angle is 5 degrees by default, or 1/72 of a circle. Is there some adjustment I need to do, to account for this wedge size and the reference area? I'm using the circular area projected into the airflow as Aref and the overall length as Iref. Should I be using the projected area just inside the wedge, or the whole wetted area from nose to tail inside the wedge, and then multiply the result by 72 or something?

Another thing I don't understand is the absence of flow separation at the bottle taper. I'm pretty certain that a 2-liter soda bottle traveling at 77 m/s through air will have flow separation there. This is no airfoil! I've seen separation on small airfoils in actual wind tunnels at lower velocities than that. The separation at the nozzle collar and nozzle opening is expected, but I can't bring myself to believe that there's laminar flow over the bottle shoulder. Here's what I get:

This has been a long slogging learning curve so far. Not just for SimFlow, but for the FreeCAD software I had to learn to create my model. I'm happy that I got ANY result at all... but I am not believing what OpenFOAM is telling me. The drag coefficient is unrealistically low, and the flow lines look too smooth.

Does anyone have any advice on how to proceed?

Last edited: