tzonehunter

- 24

- 2

Hello everyone,

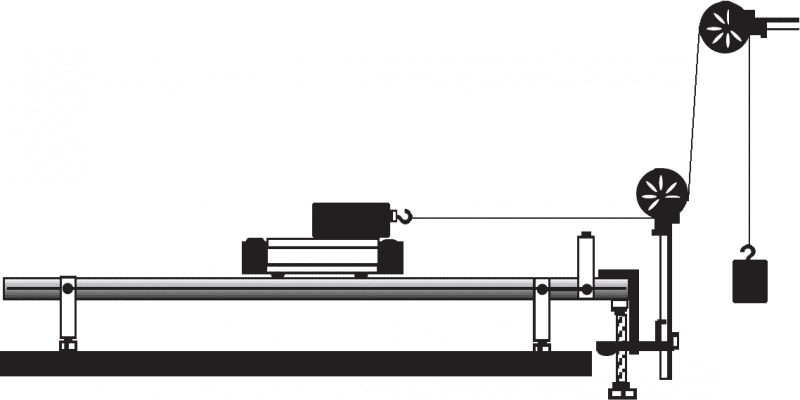

I teach Physics at a local high school. I designed a simple lab to determine the relationship between net work and kinetic energy. The diagram is shown below:

In this experiment, students release the cart from rest, while keeping displacement constant. A Vernier motion detector measures the velocity of the cart as it rolls. Students change the mass of the metal weight and repeat (50 g, 100 g, 150 g, 200 g). They then keep the mass of the metal weight constant and change the displacement. Finally, they plot FΔx vs. vf.

The plot of FΔx vs. vf^2 is linear. The slope should be 1/2m. The mass of the cart/force sensor apparatus is 645 g, so we would expect the slope of the FΔx vs. vf^2 plot to be approximately 0.32. We're seeing slopes of 0.43 - 0.47 (skewed towards the high side).

The cart and pulleys are both very low friction. The pulleys have a very low mass (they're a light weight plastic). Can anyone help explain this discrepancy?

I teach Physics at a local high school. I designed a simple lab to determine the relationship between net work and kinetic energy. The diagram is shown below:

In this experiment, students release the cart from rest, while keeping displacement constant. A Vernier motion detector measures the velocity of the cart as it rolls. Students change the mass of the metal weight and repeat (50 g, 100 g, 150 g, 200 g). They then keep the mass of the metal weight constant and change the displacement. Finally, they plot FΔx vs. vf.

The plot of FΔx vs. vf^2 is linear. The slope should be 1/2m. The mass of the cart/force sensor apparatus is 645 g, so we would expect the slope of the FΔx vs. vf^2 plot to be approximately 0.32. We're seeing slopes of 0.43 - 0.47 (skewed towards the high side).

The cart and pulleys are both very low friction. The pulleys have a very low mass (they're a light weight plastic). Can anyone help explain this discrepancy?