Faezeh

- 1

- 0

Hello,

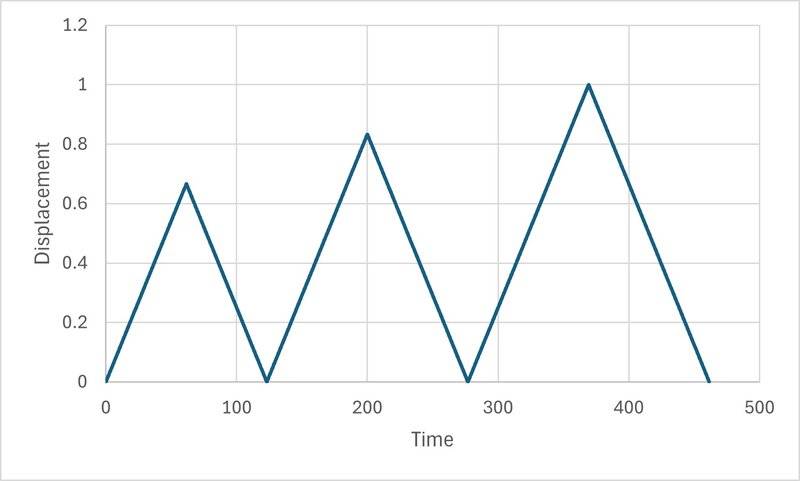

I am trying to simulate the load-unload test in Abaqus under the following loading schedule using my UMAT (which has already been validated).

As you see, the load-unload test is pure tensile with positive displacements; however as I modelled it in Abaqus the force-displacement curve as well as the stress-strain curves give me some negative forces (stresses), while theoretically all the stresses and strains should be positive. Here is the numerical load-displacement curve which is obtained from Abaqus:

View attachment 343408

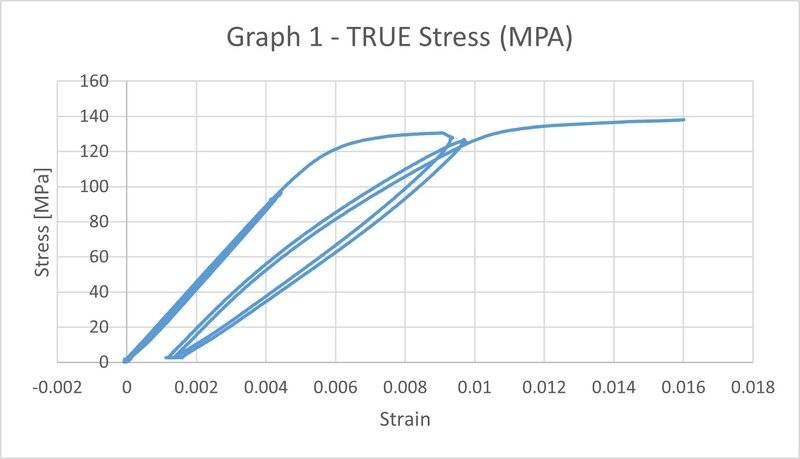

This is the experimental result (Stress-strain):

As you see there shouldn't be any negative forces (stresses) in the model. I don't know what is the problem with the model. it should be noted that I tried the model which is in this YouTube video ()

I am trying to simulate the load-unload test in Abaqus under the following loading schedule using my UMAT (which has already been validated).

As you see, the load-unload test is pure tensile with positive displacements; however as I modelled it in Abaqus the force-displacement curve as well as the stress-strain curves give me some negative forces (stresses), while theoretically all the stresses and strains should be positive. Here is the numerical load-displacement curve which is obtained from Abaqus:

View attachment 343408

This is the experimental result (Stress-strain):

As you see there shouldn't be any negative forces (stresses) in the model. I don't know what is the problem with the model. it should be noted that I tried the model which is in this YouTube video ()