SUMMARY

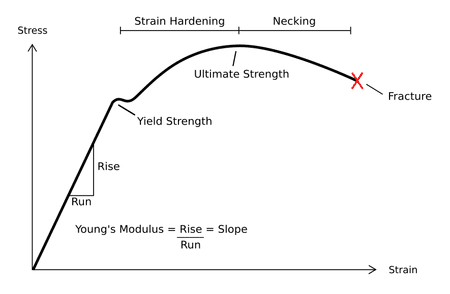

This discussion focuses on determining the slope of stress vs. strain curves, specifically how to visually assess which curve is steeper. Participants emphasize the importance of having scaled axes for accurate slope comparison, noting that without them, conclusions are unreliable. The concept of "set strain," which refers to permanent deformation, is clarified, alongside the phenomenon of "necking," where a material's cross-sectional area reduces under stress, leading to decreased tensile strength. The conversation concludes with a deeper understanding of how stress is calculated in relation to necking and the original cross-sectional area.

PREREQUISITES

- Understanding of stress vs. strain concepts

- Familiarity with the terms "necking" and "set strain"

- Basic knowledge of calculus, particularly slope calculations

- Experience with material deformation and tensile testing

NEXT STEPS

- Research "stress-strain curve analysis" for deeper insights

- Study "necking in materials" to understand its implications on tensile strength

- Explore "engineering stress vs. true stress" for clarity on stress calculations

- Learn about "Hooke's Law" and its application in material science

USEFUL FOR

Material scientists, mechanical engineers, and students studying material mechanics will benefit from this discussion, particularly those interested in the behavior of materials under stress and strain.