- 69,418

- 24,818

For a metrology (power metering) calibration test fixture at work, I'm looking for a low-cost way to generate an isolated 120Vrms (or 240Vrms) sine wave to feed into the high-impedance mesasurement circuitry.

The first test fixture used a $40k AC Mains generator instrument driving a 1kW load. As we worked through the project, it became apparent that we could handle the current sensing part of the power measurement separately, and only needed a low-current 120Vrms source to drive the voltage input of the metrology circuit (input impedance is around 5kOhms).

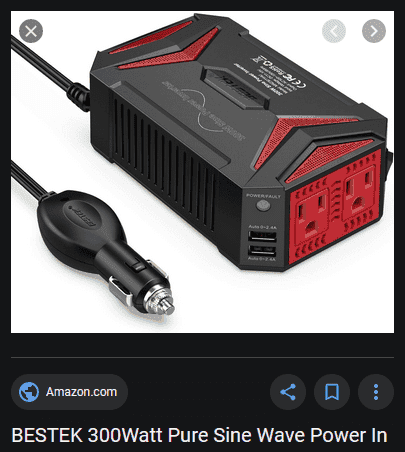

I've tried a nice little BESTEK "pure sine" inverter from 12V-->120Vrms, but it has some strange bistable behavior switching between two slightly different output voltages every 30 seconds or so (pretty hard to automate in a 0.05% accurate metrology calibration setup).

I'm starting to look into high-voltage opamps to take a low voltage signal generator output (around 3Vpp) and amplify it up to 120Vrms, but I'd be interested in any ideas that you all might have. I've also looked at using a step-up transformer to go from about 5Vrms to 120Vrms, but the transformers I've found so far have low input unductance that can't be driven by a 50 Ohm signal generator...

The first test fixture used a $40k AC Mains generator instrument driving a 1kW load. As we worked through the project, it became apparent that we could handle the current sensing part of the power measurement separately, and only needed a low-current 120Vrms source to drive the voltage input of the metrology circuit (input impedance is around 5kOhms).

I've tried a nice little BESTEK "pure sine" inverter from 12V-->120Vrms, but it has some strange bistable behavior switching between two slightly different output voltages every 30 seconds or so (pretty hard to automate in a 0.05% accurate metrology calibration setup).

I'm starting to look into high-voltage opamps to take a low voltage signal generator output (around 3Vpp) and amplify it up to 120Vrms, but I'd be interested in any ideas that you all might have. I've also looked at using a step-up transformer to go from about 5Vrms to 120Vrms, but the transformers I've found so far have low input unductance that can't be driven by a 50 Ohm signal generator...