- #1

Master1022

- 611

- 117

- Homework Statement

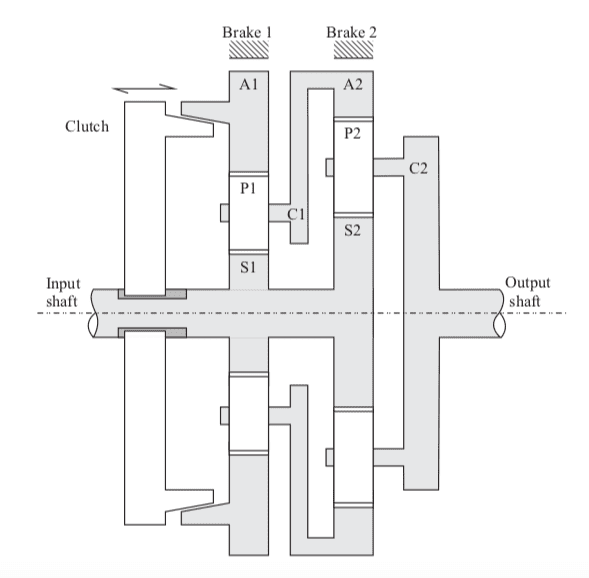

- Find the gear ratio when Brake 1 is applied, the clutch is disengaged and Brake 2 is

released.

- Relevant Equations

- [tex] \frac{\omega_1}{\omega_2} = \frac{r_2}{r_1} = \frac{N_2}{N_1} [/tex]

Hi,

Just have a question about the method in attempting this two-stage epicyclic gear-box.

We are given the following information about the number of teeth: S1 = 48, P1 = 28, S2 = 96, and P2 = 48

My attempt:

1. Work out the number of teeth for the two ring/annulus gears

From geometry, we can find that A1 = 104, A2 = 192

2. Find the ratio between the input and output (gear ratio)

So the input is [itex] \omega_{S_1} = \omega_{S_2} = \omega_{in} [/itex] and [itex] \omega_{out} = \omega_{S_2} [/itex]

Then I will start the method of considering motion with the carrier and then relative to the carrier

- I considered everything relative to C2

Here is where I went wrong and I am looking for the reason why:

- Then we know that the total [itex] \omega_{A1} = 0 [/itex] as brake 1 is applied, thus I set the motion of A1 relative to C2 as [itex] -\omega_{C_2} [/itex] (so that it sums to 0)

Why was it wrong for me to consider both stages at once (i.e. by relating C2 and A1 directly as I have done)?

- From there, I just used the gear equations to get that [itex] \omega_{S} = \omega_{C_2} \left( 1 + \frac{N_{A_1}}{N_{S_1}} \right) [/itex]. From there we can simply divide out the speed of the carrier (output) and get the gear ratio.

The solution considered the whole gearbox in two stages and did:

(overview: set up some simultaneous equations and solve for unknowns)

1. Consider speed of second stage relative to C2

2. Set an arbitrary speed of A2 relative to C2 (we now have a total of [itex] \omega_{C_2} + \omega_{Q} [/itex])

3. Now consider the first stage of the gearbox (the speed of C1 is the same as A2)

4. Now we can use the A1 has no speed condition to get relative speed of A1

5. Then we can get relative and total speeds of P1 and S1

(now we have an equation for S1 in terms of [itex] \omega_{C_2} [/itex] and [itex] \omega_{Q} [/itex])

6. To find [itex] \omega_{Q} [/itex], we once again consider the second stage of the gearbox and use relative motion of A2 to work our way down to an equation for S2 in terms of [itex] \omega_{C_2} [/itex] and [itex] \omega_{Q} [/itex]

7. Set S1 = S2 and solve for [itex] \omega_{Q} [/itex] in terms of [itex] \omega_{C_2} [/itex]

8. Substitute it back in get our ratio.

So I understand this method, but am wondering why I cannot directly consider speed of A1 relative to C2?

I realize that I have mainly provided a qualitative description of the method, but I don't really know how to write it out as the method just involves filling in tables - I will provide any clarification that is required,

Thanks in advance

Just have a question about the method in attempting this two-stage epicyclic gear-box.

We are given the following information about the number of teeth: S1 = 48, P1 = 28, S2 = 96, and P2 = 48

My attempt:

1. Work out the number of teeth for the two ring/annulus gears

From geometry, we can find that A1 = 104, A2 = 192

2. Find the ratio between the input and output (gear ratio)

So the input is [itex] \omega_{S_1} = \omega_{S_2} = \omega_{in} [/itex] and [itex] \omega_{out} = \omega_{S_2} [/itex]

Then I will start the method of considering motion with the carrier and then relative to the carrier

- I considered everything relative to C2

Here is where I went wrong and I am looking for the reason why:

- Then we know that the total [itex] \omega_{A1} = 0 [/itex] as brake 1 is applied, thus I set the motion of A1 relative to C2 as [itex] -\omega_{C_2} [/itex] (so that it sums to 0)

Why was it wrong for me to consider both stages at once (i.e. by relating C2 and A1 directly as I have done)?

- From there, I just used the gear equations to get that [itex] \omega_{S} = \omega_{C_2} \left( 1 + \frac{N_{A_1}}{N_{S_1}} \right) [/itex]. From there we can simply divide out the speed of the carrier (output) and get the gear ratio.

The solution considered the whole gearbox in two stages and did:

(overview: set up some simultaneous equations and solve for unknowns)

1. Consider speed of second stage relative to C2

2. Set an arbitrary speed of A2 relative to C2 (we now have a total of [itex] \omega_{C_2} + \omega_{Q} [/itex])

3. Now consider the first stage of the gearbox (the speed of C1 is the same as A2)

4. Now we can use the A1 has no speed condition to get relative speed of A1

5. Then we can get relative and total speeds of P1 and S1

(now we have an equation for S1 in terms of [itex] \omega_{C_2} [/itex] and [itex] \omega_{Q} [/itex])

6. To find [itex] \omega_{Q} [/itex], we once again consider the second stage of the gearbox and use relative motion of A2 to work our way down to an equation for S2 in terms of [itex] \omega_{C_2} [/itex] and [itex] \omega_{Q} [/itex]

7. Set S1 = S2 and solve for [itex] \omega_{Q} [/itex] in terms of [itex] \omega_{C_2} [/itex]

8. Substitute it back in get our ratio.

So I understand this method, but am wondering why I cannot directly consider speed of A1 relative to C2?

I realize that I have mainly provided a qualitative description of the method, but I don't really know how to write it out as the method just involves filling in tables - I will provide any clarification that is required,

Thanks in advance

Last edited: