berkeman said:

In addition, the AC Mains Hot wire that comes into the machine must go immediately through a fuse and a switch of some kind before going into the power supply. Those connections also need to be very reliable (often made with spade lug type connectors).

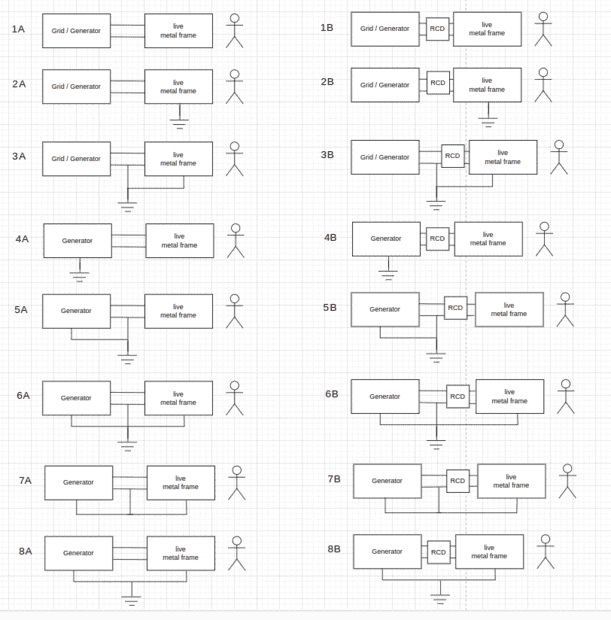

All of this is done so that a single fault (a single thing going wrong) cannot energize the metal enclosure of the machine and create a shock hazard.

In common safety standards (IEC-950 et. al.), fuses (and circuit breakers, etc.) are used for fire protection, not for protection against hazardous voltages. There are single fault scenarios where fuses simply aren't reliable or fast enough to deenergize the fault. This is unlike GFCI (or RCD*) devices which are designed specifically to be fast and sensitive enough, and to measure the relevant parameter (fault current) to save humans.

Thus the ground wire(s) are required to have good mechanical construction and sufficient conductivity to reduce the accessible voltage to safe levels in a single fault condition essentially forever. In this scenario, it isn't uncommon for things to get hot and maybe start a fire. This is where fuses come into play; as well as other requirements like accessible temperature, insulation ratings etc.

*Yep, I'm American! RCD confuses me, but I think I've fixed that by pretending y'all really meant to say GFCI, LOL.

PS: The safety standards I'm familiar with (certainly not all of them!) will require safe accessible voltages, currents, temperatures, etc. under single fault conditions. These are typically written as performance standards, not construction standards.

This means that you can use fuses, or whatever else you like, to prevent a specific hazard. But, you'll have to convince an inspector, usually with LOTS of testing, to prove your design is safe. Of course everyone, designers and inspectors, resort to standard solutions to avoid the complexity. This I all learned the hard way back in the day getting safety approvals for huge Ion Lasers, which are really difficult from a "normal construction methods" standpoint. The practical cost was we had to do lots of fault testing and find really knowledgeable (i.e. rare and expensive**) inspectors to get our stuff done. Your normal "new grad safety guy" can't handle it, they don't really know the real requirements. All they every see are standard products.

None the less, if you've ever waded through the trip characteristics of fuses or circuit breakers with a "worst case" mind set, you'll soon give up on them for doing anything quickly.

** Short answer, back in the day, they probably work for TUV, definitely not ever, ever, ever UL.