omka

hello,

Could you please help me to understand how this steel ingot rolling system works.

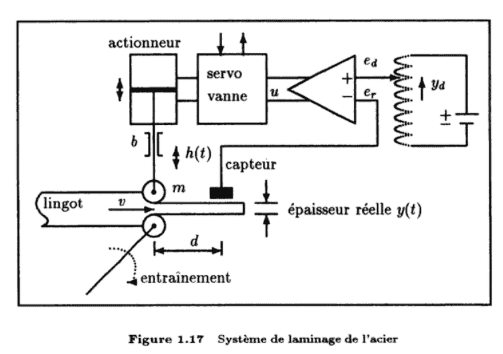

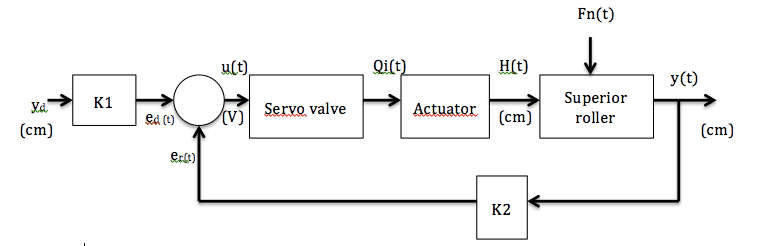

The simplified diagram of a rolling mill is shown in the figure attached. The upper roller of mass m is driven by an electro-hydraulic actuator his objectif is to adjust the thickness to be given to the ingot moving to the right. The inferior roller is driven by a synchronous motor via a flywheel, his role is to compensate the sudden forces which act on the roll without increasing the power of the engine. The thickness y (t) of the laminated ingot is measured using a contact sensor of factor K2. The desired thickness is set using a potentiometer of factor k1. The normal force, FN, acting on the upper roller is considered disturbance.

My questions:

1. how can the inferior roll compensate the sudden forces which act on the superior roll without increasing the power of the synchronous motor?

2. What can be sudden forces (example) ?I’ve tried to model this "steel ingot rolling automatic control system" graphically.

It is correct ? Should i add the command of the inferior roller in my graphical model? i just want to understand the feedback system control

It is correct ? Should i add the command of the inferior roller in my graphical model? i just want to understand the feedback system control

Please this is not homework. thank you in advance

Could you please help me to understand how this steel ingot rolling system works.

The simplified diagram of a rolling mill is shown in the figure attached. The upper roller of mass m is driven by an electro-hydraulic actuator his objectif is to adjust the thickness to be given to the ingot moving to the right. The inferior roller is driven by a synchronous motor via a flywheel, his role is to compensate the sudden forces which act on the roll without increasing the power of the engine. The thickness y (t) of the laminated ingot is measured using a contact sensor of factor K2. The desired thickness is set using a potentiometer of factor k1. The normal force, FN, acting on the upper roller is considered disturbance.

My questions:

1. how can the inferior roll compensate the sudden forces which act on the superior roll without increasing the power of the synchronous motor?

2. What can be sudden forces (example) ?I’ve tried to model this "steel ingot rolling automatic control system" graphically.

Please this is not homework. thank you in advance