Discussion Overview

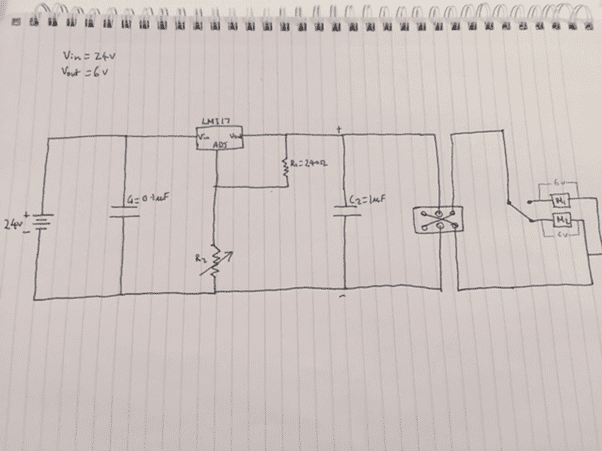

The discussion revolves around calculating the output current of a voltage regulator circuit designed to supply power to motors after stepping down the voltage from 24V to 6V. Participants explore methods to determine the current draw of the motors under various conditions, including load and direction changes.

Discussion Character

- Technical explanation

- Debate/contested

- Experimental/applied

Main Points Raised

- One participant seeks assistance in finding the output current for motors after voltage regulation, expressing confusion about the calculations needed.

- Another participant suggests measuring the current directly, noting that the motor specifications may not provide sufficient information about current draw at 6V.

- A third participant emphasizes the importance of measuring current with an ammeter, while cautioning that the meter's resistance might affect readings.

- It is mentioned that the LM317 regulator has built-in current limiting, with a typical rating around 1.5A, which could be relevant for the circuit's operation.

- Discussion includes the impact of mechanical load on current draw, with references to full load and locked rotor current ratings of the motors, indicating that these factors can significantly affect performance.

- Concerns are raised about the potential for the LM317 to enter overload limiting if the motors draw locked rotor amps during direction changes, suggesting the need for adequate heat sinking.

Areas of Agreement / Disagreement

Participants generally agree on the necessity of measuring current to determine motor requirements, but there is no consensus on the best method to do so or the implications of motor characteristics on current draw.

Contextual Notes

Limitations include the lack of specific motor current ratings and the potential variability in current draw based on mechanical load and operational conditions. The discussion does not resolve the best approach for measuring current or the adequacy of the LM317 for the application.