Discussion Overview

The discussion revolves around troubleshooting a homemade DC motor that is not functioning as expected. Participants explore various design aspects, potential issues, and suggestions for improvement related to the motor's construction and operation.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

Main Points Raised

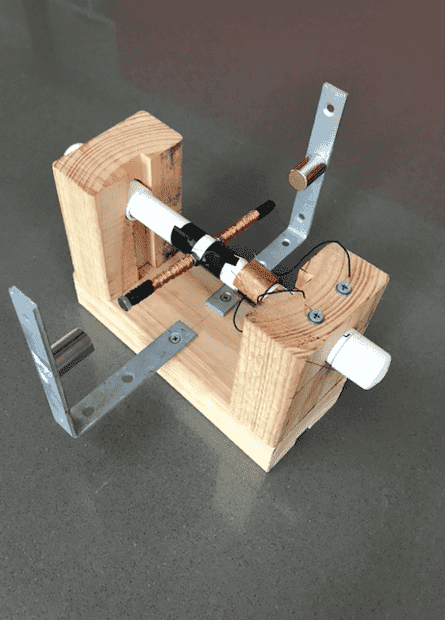

- One participant describes their DC motor setup, noting that it generates heat and sparks but does not operate, seeking advice on potential design flaws.

- Another participant suggests testing the rotor's behavior with and without power to compare acceleration and braking effects.

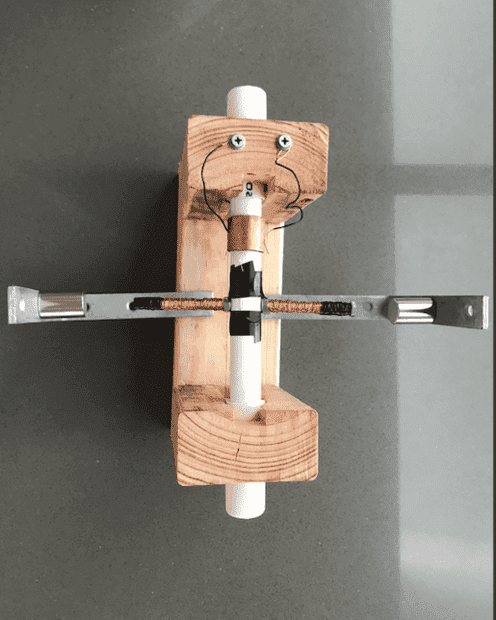

- Checking the polarity of the magnetic fields and commutator is recommended by multiple participants to ensure correct configuration.

- Reducing the gap between the magnets and the coils is proposed, as solenoids may not project their magnetic field as effectively as assumed.

- Concerns are raised about the possibility of the current flow causing braking rather than rotation, with one participant noting they have already reduced the gap between the magnets.

- Participants suggest observing torque during rotation and checking for bearing friction, commutator timing, and the number of turns in the windings as factors affecting performance.

- One participant shares an experience where incorrect winding direction of coils led to non-functionality, emphasizing the importance of consistent winding direction across the armature.

- Another participant expresses concern that the motor has never produced movement, attributing this to the weight of the shaft and armatures possibly being too heavy relative to the windings.

- Repeated emphasis on checking the polarity of the coils and magnets is made, indicating it as a critical point in the troubleshooting process.

- A later reply urges the original poster to report back on the outcomes of following the suggestions provided, highlighting the collaborative nature of the troubleshooting effort.

Areas of Agreement / Disagreement

Participants generally agree on the importance of checking the polarity of the coils and magnets, as well as the need to explore various mechanical and electrical adjustments. However, there are multiple competing views on the specific causes of the motor's failure and the best approaches to resolve the issues, leaving the discussion unresolved.

Contextual Notes

Participants express uncertainty regarding the effects of current flow on motor operation, the impact of mechanical weight, and the specific configurations of the coils and magnets. There are also unresolved questions about the effectiveness of the proposed solutions.