novop

- 124

- 0

Hi,

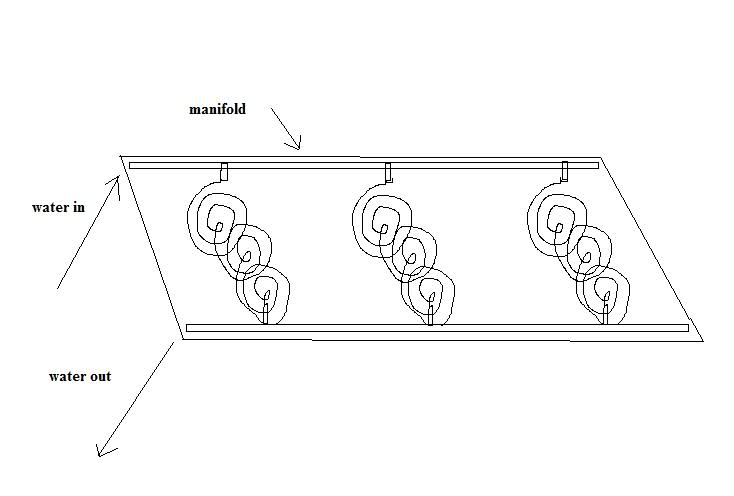

I'm having a problem building a sort of pool heater for my backyard. I've assembled some black tubing into 9 spirals, making 3 groups of 3, and then attaching the groups of spirals to a manifold, to supply equal pressure to each group, see pic below.

The water is pumped up to my roof, where the manifold is, by a pump at about 6 psi, and then the water (is supposed to) runs through the hot tubes back into the pool. The problem is this: only the group of 3 spirals on the right get water flowing through them. The other 2 groups (or 6 spirals) get no water flow.

By disconnecting the group on the left and then connecting just ONE spiral, the pressure is so weak it doesn't even flow through the one spiral. Doing the same to the middle group, I find that the water can flow through one spiral.

Shouldn't the manifold be supplying equal pressure to each group? Why is it then that the pressure on the leftmost group is very weak, the middle intermediate, and the best pressure is on the right? What can I do to improve this? Thanks in advance.

I'm having a problem building a sort of pool heater for my backyard. I've assembled some black tubing into 9 spirals, making 3 groups of 3, and then attaching the groups of spirals to a manifold, to supply equal pressure to each group, see pic below.

The water is pumped up to my roof, where the manifold is, by a pump at about 6 psi, and then the water (is supposed to) runs through the hot tubes back into the pool. The problem is this: only the group of 3 spirals on the right get water flowing through them. The other 2 groups (or 6 spirals) get no water flow.

By disconnecting the group on the left and then connecting just ONE spiral, the pressure is so weak it doesn't even flow through the one spiral. Doing the same to the middle group, I find that the water can flow through one spiral.

Shouldn't the manifold be supplying equal pressure to each group? Why is it then that the pressure on the leftmost group is very weak, the middle intermediate, and the best pressure is on the right? What can I do to improve this? Thanks in advance.