SUMMARY

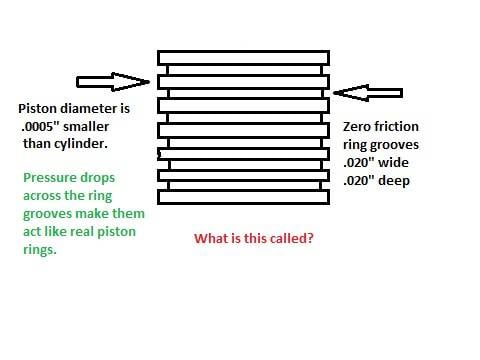

The forum discussion centers on the design and functionality of zero friction piston rings, particularly in the context of Stirling engines. Participants reference groove dimensions of .020" wide and .020" deep, which create pressure differentials that enhance engine performance. The concept of labyrinth seals is introduced, highlighting their role in reducing flow velocity and improving sealing efficiency. Users share personal experiences and technical insights regarding various groove shapes and their impact on airflow and engine efficiency.

PREREQUISITES

- Understanding of Stirling engine mechanics

- Familiarity with labyrinth seal technology

- Knowledge of fluid dynamics and airflow principles

- Experience with piston ring design and performance optimization

NEXT STEPS

- Research "Labyrinth seal design principles" for improved sealing techniques

- Explore "Stirling engine efficiency optimization" methods

- Investigate "groove design impact on airflow" in piston applications

- Study "eddy current effects in fluid dynamics" for enhanced performance analysis

USEFUL FOR

Engine designers, mechanical engineers, and hobbyists interested in optimizing Stirling engine performance and understanding advanced sealing technologies.

.

.