- #1

Teeg

- 2

- 0

- TL;DR Summary

- TL DR: Am I using correct formula for calculating Volumetric Flow rate through Venturi Tube

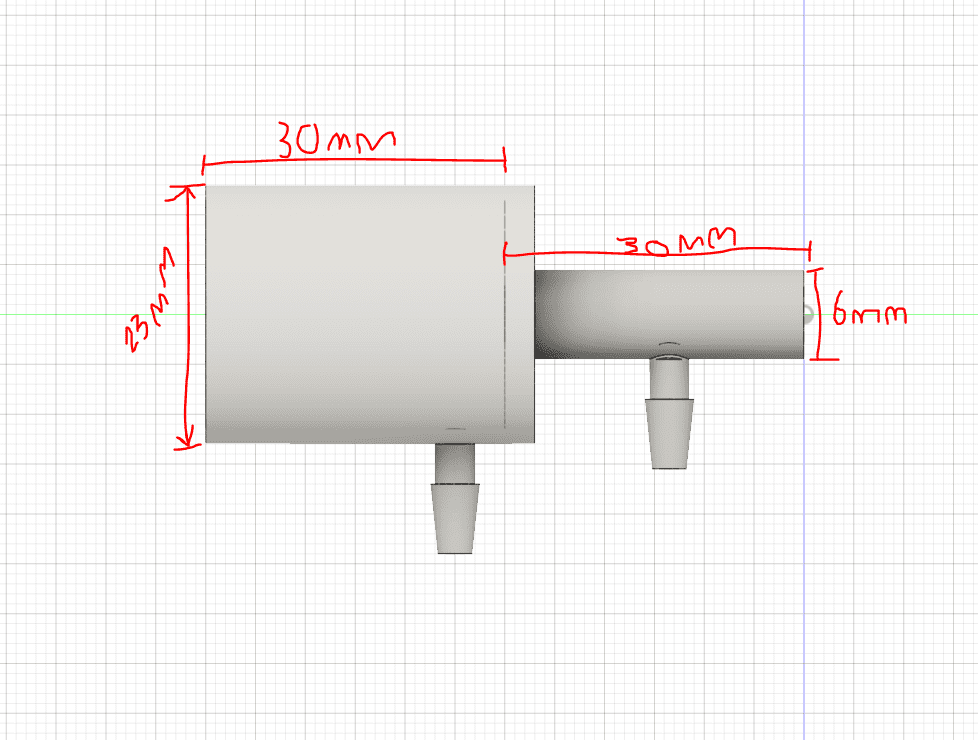

Hi, I have designed a simple Venturi meter to measure pressure differential across to section of the pipe as pictured. However in calculations I am not sure if I am doing something wrong. I am trying to calculate Volumetric flow rate in L/s.

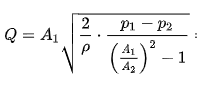

I am using Bernoulli Equation of the Venturi meter as above

From my MPX5010 DP Sensor I am getting a pressure differential of 222.2 pa.

A1 is cross sectional area of first part of the tube = Pi * R^2 = 0.000415 M^2

A2 = Pi* R^2 = 0.0000283 M^2

P = Density of air = 1.225

P1-P2 = DeltaP = 222.2 Pa

Plugging all into the equation above I am getting a volumetric flowrate = 0.000539783 M^3/s

Multiply by 1000 = 0.539783 L/s

Is this correct, is the formula correct ? I have seen multiple different formulas stipulated online.

Thank you

I am using Bernoulli Equation of the Venturi meter as above

From my MPX5010 DP Sensor I am getting a pressure differential of 222.2 pa.

A1 is cross sectional area of first part of the tube = Pi * R^2 = 0.000415 M^2

A2 = Pi* R^2 = 0.0000283 M^2

P = Density of air = 1.225

P1-P2 = DeltaP = 222.2 Pa

Plugging all into the equation above I am getting a volumetric flowrate = 0.000539783 M^3/s

Multiply by 1000 = 0.539783 L/s

Is this correct, is the formula correct ? I have seen multiple different formulas stipulated online.

Thank you