_Patrick_

- 1

- 0

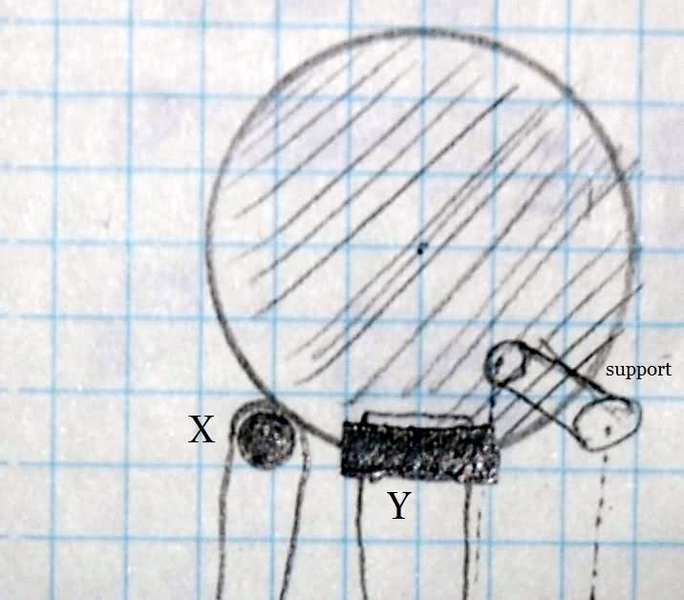

Hi there - I'm trying to build a decorational device that holds a rather heavy ball and I want to be able to control it's "movement/roll" in the X and Y directions (they are horizontal as well as orthogonal).

The two black cylinders (X and Y) aren't floating, but I forgot to draw their support pillars. They are wrapped into a rubber band each, which both are attached to two differrent motors in order to make them rotate.

The support is just an attempt to not drop the ball and is placed "behind" it from our point of view.

I have 2 questions:

1) If only the X-motor runs, will there be such a great friction between the ball and the Y-rubber that this configuration won't work?

2) Do you have any other ideas where the motion will come from external motors and rubber bans?

The two black cylinders (X and Y) aren't floating, but I forgot to draw their support pillars. They are wrapped into a rubber band each, which both are attached to two differrent motors in order to make them rotate.

The support is just an attempt to not drop the ball and is placed "behind" it from our point of view.

I have 2 questions:

1) If only the X-motor runs, will there be such a great friction between the ball and the Y-rubber that this configuration won't work?

2) Do you have any other ideas where the motion will come from external motors and rubber bans?