- #1

jT990

- 1

- 0

Hello all,

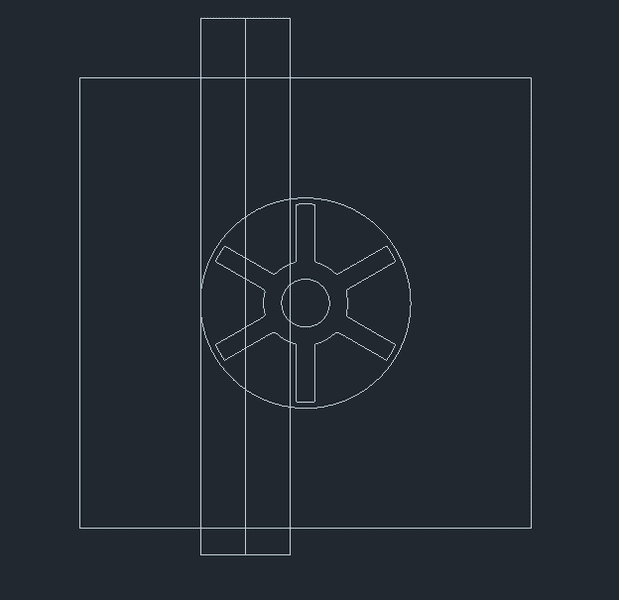

I am after some advice regarding a hall sensor type air flow meter.

I know from experience that most hall sensor flow meters allow a bypass of fluid around the turbine/fan. However I would like to know what would happen if this was the case of the design below.

Specifications;

Inlet air velocity 0-11.5ms-1

Inlet ID 1.5mm

Turbine diameter: 5mm

Air gap between turbine and housing: 0.1mm

I assume two things will happen,

1.) the turbine itself will impede intake air velocity and eventually reach zero.

and/or 2.) the turbine will rotate too fast and the turbulence created inside the housing will in turn impede intake air.

I will attach calculations shortly.Thanks in advance.

I am after some advice regarding a hall sensor type air flow meter.

I know from experience that most hall sensor flow meters allow a bypass of fluid around the turbine/fan. However I would like to know what would happen if this was the case of the design below.

Specifications;

Inlet air velocity 0-11.5ms-1

Inlet ID 1.5mm

Turbine diameter: 5mm

Air gap between turbine and housing: 0.1mm

I assume two things will happen,

1.) the turbine itself will impede intake air velocity and eventually reach zero.

and/or 2.) the turbine will rotate too fast and the turbulence created inside the housing will in turn impede intake air.

I will attach calculations shortly.Thanks in advance.

Attachments

Last edited: