Buns_of_Steel

- 4

- 0

Hi,

I'm looking for some help regarding heat transfer through some sandwiched materials.

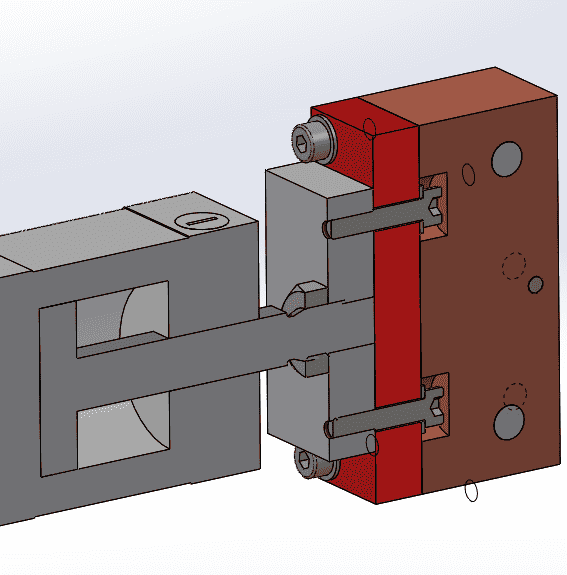

We have a pneumatic cylinder with the stainless steel 303 cylinder rod attached to a block of aluminium 6082 t6 50mm high x 40mm wide x 10mm deep. This block is attached to a block of polyurethane, shore a70 70mm high x 40mm wide x 10mm deep which is then attached to a block of copper c101 70mm high x 40mm wide x 30mm deep. The copper block is heated to a temperature of 250 degrees Celsius. A cross section of the layout is shown below.

What we want to do is treat the arrangement as simply as possible i.e. ignoring the fasteners, holes etc and calculate the heat transfer through the copper, polyurethane, aluminium and into the cylinder rod and get a rough idea of what the temperature will be in the cylinder rod would be.

I'm at a bit of a loss as to where to start with this.

If anyone could help with a basic procedure of how to tackle this problem and what the relevant equations are it would be much appreciated.

Cheers

David

I'm looking for some help regarding heat transfer through some sandwiched materials.

We have a pneumatic cylinder with the stainless steel 303 cylinder rod attached to a block of aluminium 6082 t6 50mm high x 40mm wide x 10mm deep. This block is attached to a block of polyurethane, shore a70 70mm high x 40mm wide x 10mm deep which is then attached to a block of copper c101 70mm high x 40mm wide x 30mm deep. The copper block is heated to a temperature of 250 degrees Celsius. A cross section of the layout is shown below.

What we want to do is treat the arrangement as simply as possible i.e. ignoring the fasteners, holes etc and calculate the heat transfer through the copper, polyurethane, aluminium and into the cylinder rod and get a rough idea of what the temperature will be in the cylinder rod would be.

I'm at a bit of a loss as to where to start with this.

If anyone could help with a basic procedure of how to tackle this problem and what the relevant equations are it would be much appreciated.

Cheers

David