Apple&Orange

- 28

- 2

Hi guys

I'm looking to calculate the static frictional force for a hinge

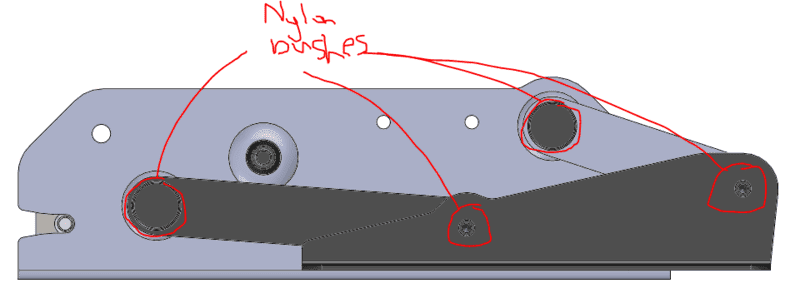

Below is a CAD image of the component I am testing.

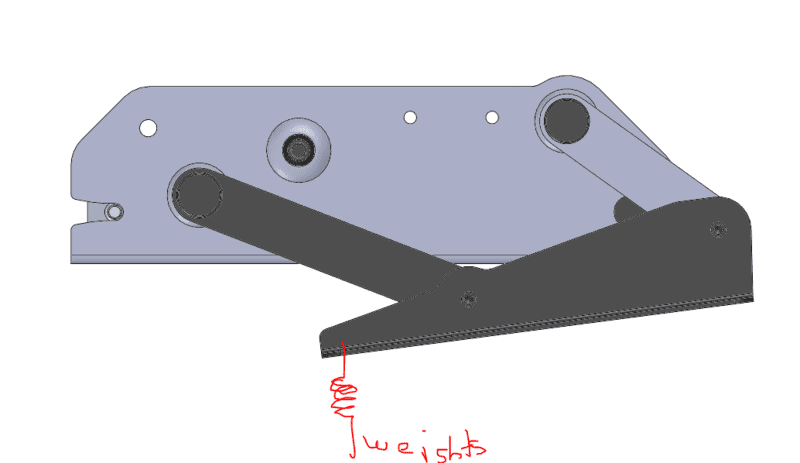

I am thinking of attaching a hook onto the plate as shown below, and continuously add weights at the end of the hook until the hinge begins to move.

By multiplying the weight with the acceleration of gravity, will this give me the Static Frictional Force?

I'm looking to calculate the static frictional force for a hinge

Below is a CAD image of the component I am testing.

I am thinking of attaching a hook onto the plate as shown below, and continuously add weights at the end of the hook until the hinge begins to move.

By multiplying the weight with the acceleration of gravity, will this give me the Static Frictional Force?