Rawllet

- 1

- 0

- TL;DR Summary

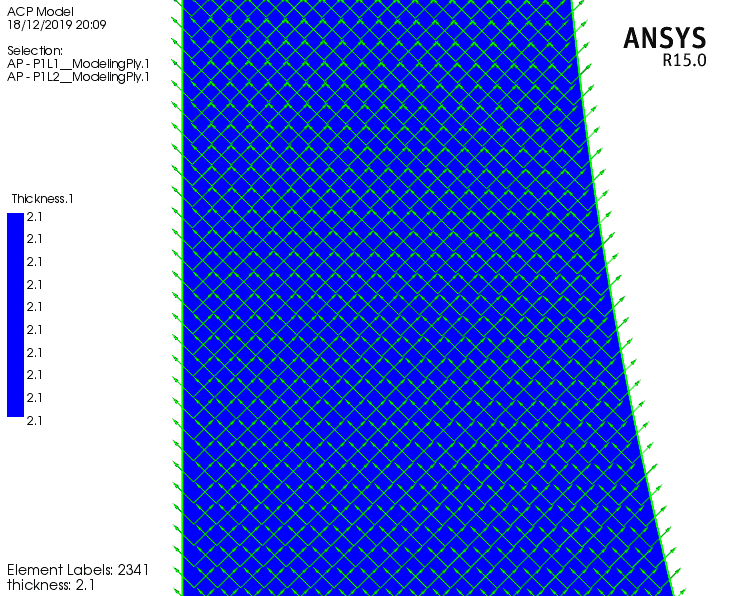

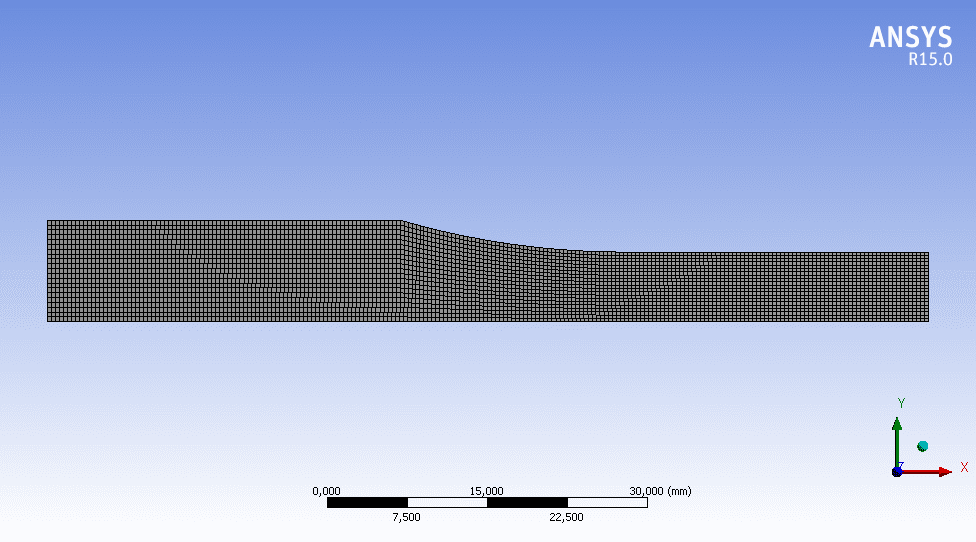

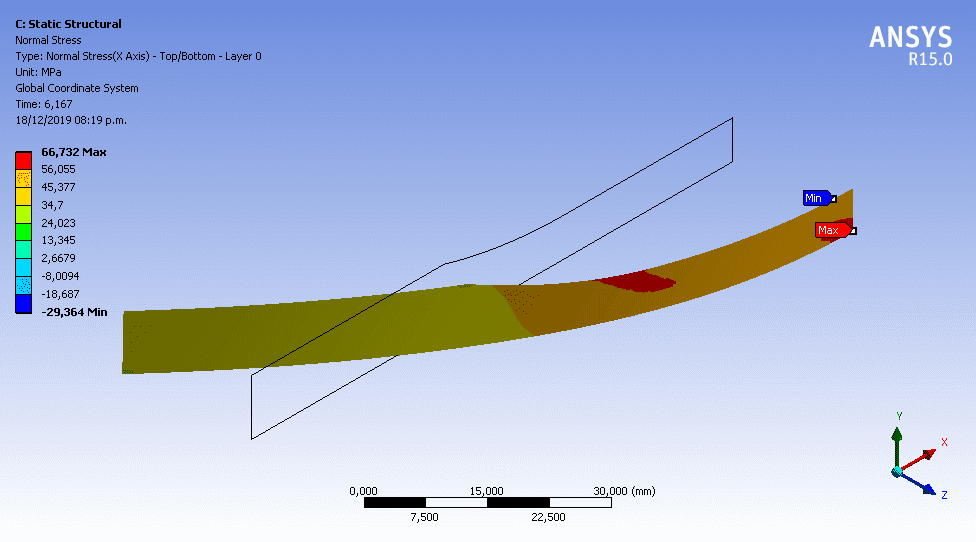

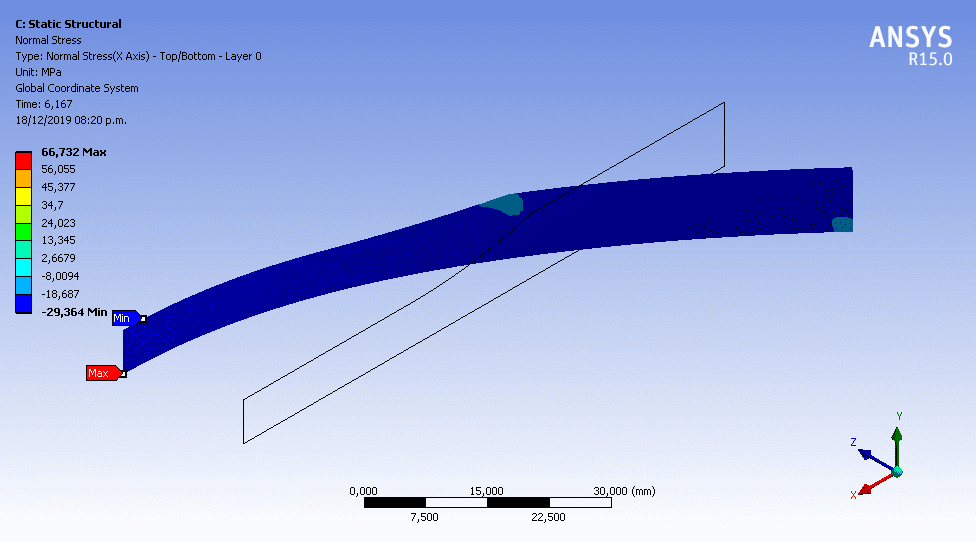

- Tensile test, using ACP Pre and Static Structural modules, of a fiber glass laminate with 6 layers orientated +/-45°.

Hello everyone!

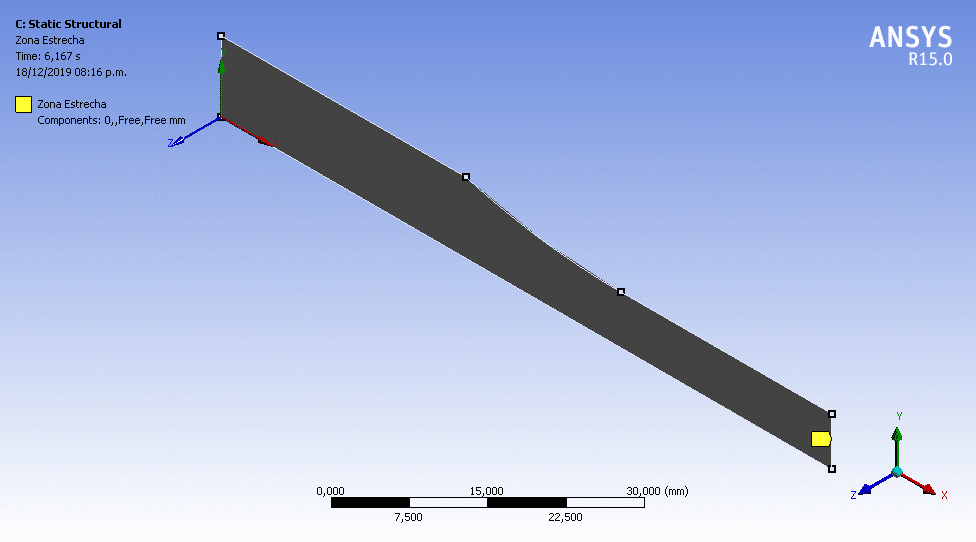

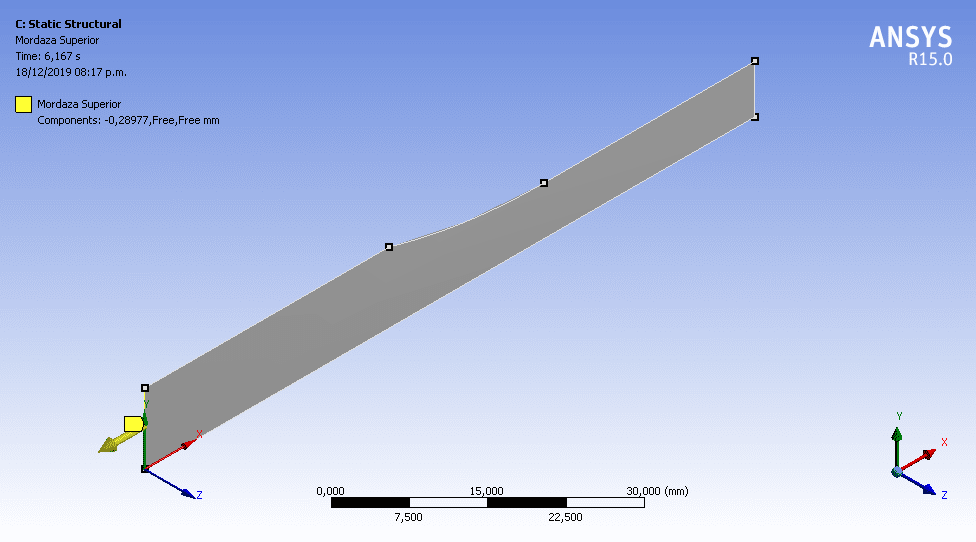

I am trying to modelate a tensile test of dumbbell-shaped specimen under ACP PrePost and Static Structural modules. The laminate I am configuring consists of 6 laminas of E FiberGlass orientated +/-45°. For simplicity I am working with 1/4 of the geometry and the boundary conditions are 2 displacements. One that let's movement only in X axis and the other only let's movement in Y and Z axis.

My problem is a strange deflection that is shown in the solutions spot and I do not know what could be the reason of it. I don't know if is because of the boundary conditions or maybe a bad laminate configuration.

I wii be very thankful for any help. I attached a few photos that could help in the understanding of the problem.

Thank you in advance.

I am trying to modelate a tensile test of dumbbell-shaped specimen under ACP PrePost and Static Structural modules. The laminate I am configuring consists of 6 laminas of E FiberGlass orientated +/-45°. For simplicity I am working with 1/4 of the geometry and the boundary conditions are 2 displacements. One that let's movement only in X axis and the other only let's movement in Y and Z axis.

My problem is a strange deflection that is shown in the solutions spot and I do not know what could be the reason of it. I don't know if is because of the boundary conditions or maybe a bad laminate configuration.

I wii be very thankful for any help. I attached a few photos that could help in the understanding of the problem.

Thank you in advance.