CassieFordham

- 13

- 0

I was reading about bipolar plate batteries, where the plates function as both the anode for one cell and cathode for the next cell, in series. It seems to me that the same idea should work to create a capacitor of higher voltage.

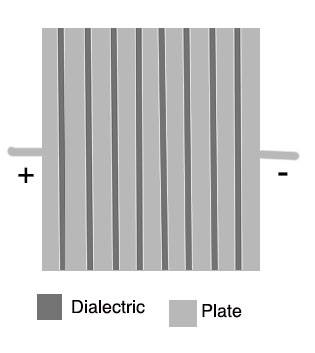

If I had a dielectric material that had dielectric strength of of 0.8 volts, and created a 9 plate, 8 dielectric capacitor like the picture below, would it work as a 6 volt capacitor?

If I had a dielectric material that had dielectric strength of of 0.8 volts, and created a 9 plate, 8 dielectric capacitor like the picture below, would it work as a 6 volt capacitor?