Andromeda1992

- 1

- 0

- TL;DR Summary

- I need to design a tool to appropriately position and align my compression samples

Hello all,

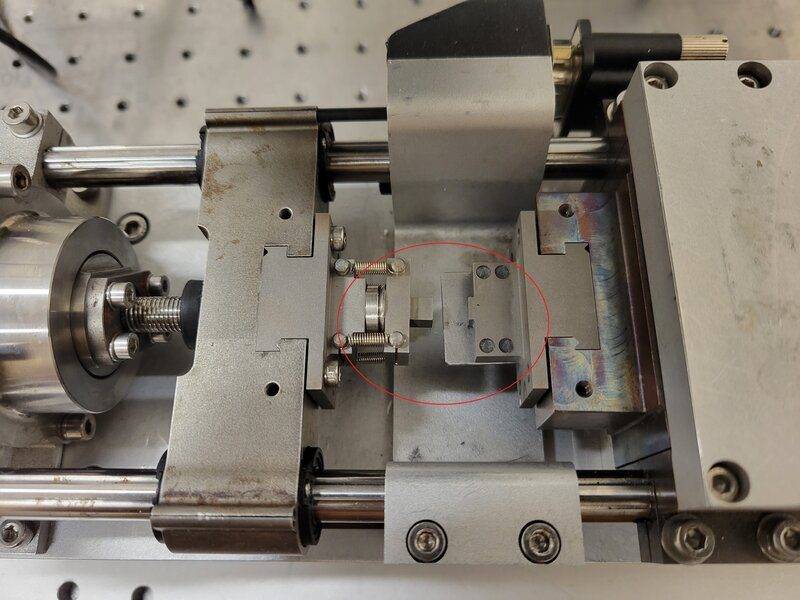

I am looking for some design ideas. I need to do some compression testing and here is my testing platens:

The platens are small (5mm*5 mm) and my samples are even smaller with the cross section of 3mm*2.4mm, so it would be difficult to both position them within the platens and align them with the center of the platens. I need to design a simple tool like a jig or something to help me position and align my samples. I can print that with a 3D printer. Does anyone have any design idea for such a tool. I'd really appreciate your ideas.

I am looking for some design ideas. I need to do some compression testing and here is my testing platens:

The platens are small (5mm*5 mm) and my samples are even smaller with the cross section of 3mm*2.4mm, so it would be difficult to both position them within the platens and align them with the center of the platens. I need to design a simple tool like a jig or something to help me position and align my samples. I can print that with a 3D printer. Does anyone have any design idea for such a tool. I'd really appreciate your ideas.

Last edited by a moderator: