- #1

reuben19

- 5

- 0

Hi! Can someone please point me in the right direction with this? I'm having trouble and any form of help would be greatly appreciated :) It's a homework question!

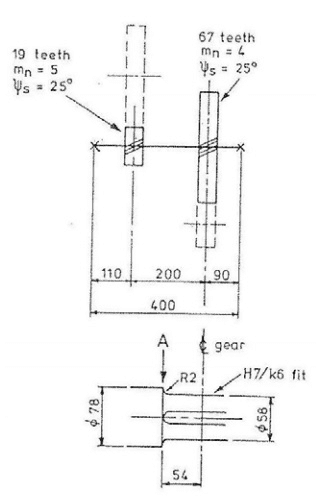

A rotating shaft is able to transmit 4kW of power whilst rotating with a speed of 450 revolutions per minute. The maximum torque at the start period is equal to 2.6 FLT. Power can be applied in either direction and the helical gears are arranged to give opposing directions for the axial force generated by the tooth action. The shaft is manufactured from CS1030. Effects of inertia are not significant. Any resultant thrust can be taken at the left hand bearing. The number of revolutions of shaft per year > 900 The number of mechanism starts per year > 600

A) Draw bending moment diagrams for the horizontal and vertical planes for normal, full load, maximum speed (450 rev/min), running conditions. (Use the tension condition between gear and pinion).

B) From (A), determine the bending moment absolute at point A.

C) Assuming the machine starts under full load, use the AS 1403 shaft design code and check the shaft at point A. The calculations are to be done adopting 50 mm for the diameter at the step as specified. Material of manufacture is CS1030.

D) If the diameter (58mm) mentioned in (C) was not known, use AS1403 and determine a trial diameter.

E) Assuming the bearings are self-aligning ball, with a diameter of 55 at the left hand side and 50 at the right hand side, choose the most appropriate bearings. Design for 32000 hours life.

A rotating shaft is able to transmit 4kW of power whilst rotating with a speed of 450 revolutions per minute. The maximum torque at the start period is equal to 2.6 FLT. Power can be applied in either direction and the helical gears are arranged to give opposing directions for the axial force generated by the tooth action. The shaft is manufactured from CS1030. Effects of inertia are not significant. Any resultant thrust can be taken at the left hand bearing. The number of revolutions of shaft per year > 900 The number of mechanism starts per year > 600

A) Draw bending moment diagrams for the horizontal and vertical planes for normal, full load, maximum speed (450 rev/min), running conditions. (Use the tension condition between gear and pinion).

B) From (A), determine the bending moment absolute at point A.

C) Assuming the machine starts under full load, use the AS 1403 shaft design code and check the shaft at point A. The calculations are to be done adopting 50 mm for the diameter at the step as specified. Material of manufacture is CS1030.

D) If the diameter (58mm) mentioned in (C) was not known, use AS1403 and determine a trial diameter.

E) Assuming the bearings are self-aligning ball, with a diameter of 55 at the left hand side and 50 at the right hand side, choose the most appropriate bearings. Design for 32000 hours life.