ella_lei9

- 10

- 0

How to calculate 3D Principal stresses?

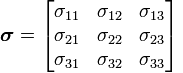

If I got the values of 6 stress tensors:

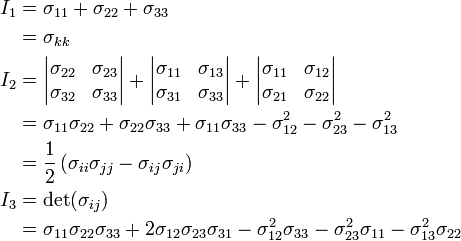

Then I can calculate the values for the 3 stress invariants I1, I2 and I3:

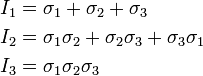

I also know the relationship between the stress invariants and principal stresses:

So how can I calculate the values for the 3 principal stresses?

I can find some simple stress calculator on-line to get the results straight away, but I need the algorithm step for the calculation. In the other word, I need the individual equations for S1, S2 and S3, then I can do the calculation myself without using any software calculator or speardsheet!

Thanks a lot!

If I got the values of 6 stress tensors:

Then I can calculate the values for the 3 stress invariants I1, I2 and I3:

I also know the relationship between the stress invariants and principal stresses:

So how can I calculate the values for the 3 principal stresses?

I can find some simple stress calculator on-line to get the results straight away, but I need the algorithm step for the calculation. In the other word, I need the individual equations for S1, S2 and S3, then I can do the calculation myself without using any software calculator or speardsheet!

Thanks a lot!