kanibal

- 2

- 0

Hello

i am working on a small clutch cable testing machine this machine can give the lifetime of clutch cable

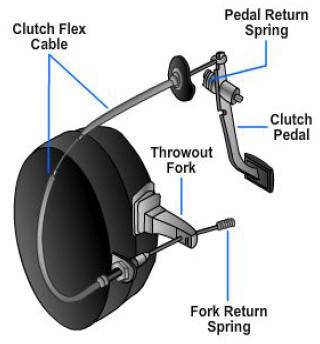

i need some assistance to figure out how much forces i need to apply on this mechanism , and because the cable related directly in the clutch I'm asking if the force in the clutch in the same us what we give to the pedal example : if i push the pedal with 200 N how mach force is applied into release the clutch it is the same 200 N or more and why !

this is the mechanism i made

i am working on a small clutch cable testing machine this machine can give the lifetime of clutch cable

i need some assistance to figure out how much forces i need to apply on this mechanism , and because the cable related directly in the clutch I'm asking if the force in the clutch in the same us what we give to the pedal example : if i push the pedal with 200 N how mach force is applied into release the clutch it is the same 200 N or more and why !

this is the mechanism i made