dhirendra pandey

- 2

- 0

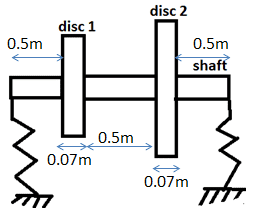

Hi! I am new in ansys. I am doing rotor dynamic study of a high speed rotating shaft. the shaft comprise of two discs and at the it ends the shaft is supported by the bearing I am facing problem in modelling stage please tell me how to model the bearing and disc briefly.I am uploading the image and these are the dimension.Please Do reply.

Diameter of disc 1 = 0.28m

Diameter of disc 2 = 0.35m

Diameter of shaft = 0.05m

Length of the shaft = 1.5m

Thickness of disc 1, disk 2 = 0.07m

Modulus of Elasticity = 211 GN/m^2

Modulus of Rigidity = 81.2 GN/m^2

Density = 7800 kg/m^3

Speed = 4000 rpm

Bearing stiffness = 1 MN/m

Diameter of disc 1 = 0.28m

Diameter of disc 2 = 0.35m

Diameter of shaft = 0.05m

Length of the shaft = 1.5m

Thickness of disc 1, disk 2 = 0.07m

Modulus of Elasticity = 211 GN/m^2

Modulus of Rigidity = 81.2 GN/m^2

Density = 7800 kg/m^3

Speed = 4000 rpm

Bearing stiffness = 1 MN/m